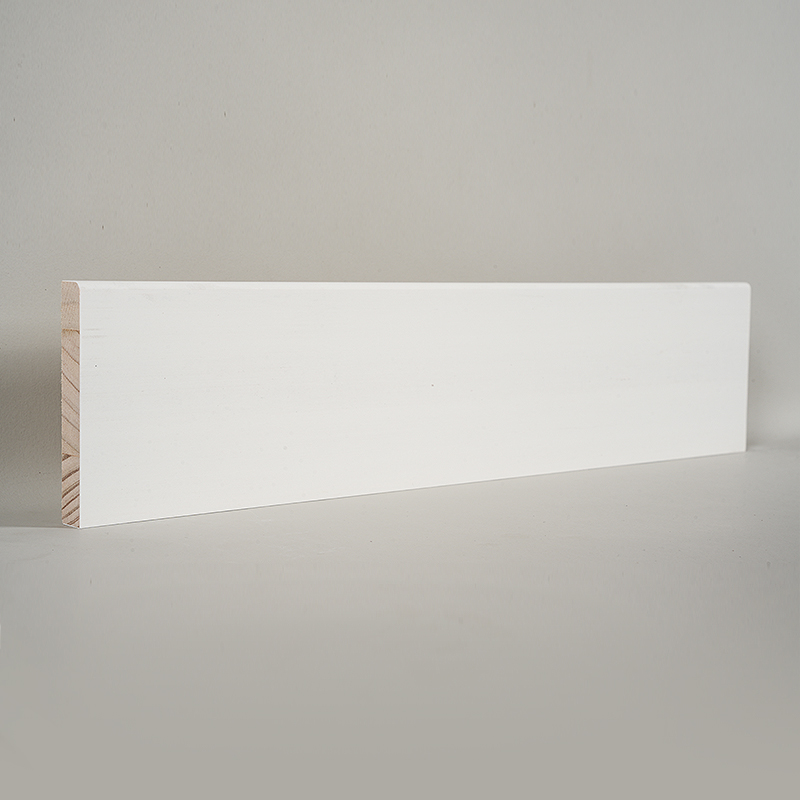

What Determines the Quality and Performance of a White Primed Skirting Board?

In modern interior construction and decorative systems, the white primed skirting board has evolved into a fundamental component that bridges visual design, structural protection, and functional enhancement. Whether used in residential renovations, commercial interiors, hospitality projects, or integrated wall systems, primed skirting boards play a critical role in finishing standards and design continuity. As material technologies advance and aesthetic preferences diversify, the demand for higher-quality skirting boards with superior stability, durability, and surface precision continues to increase.

Industry Role and Functional Positioning of White Primed Skirting Boards

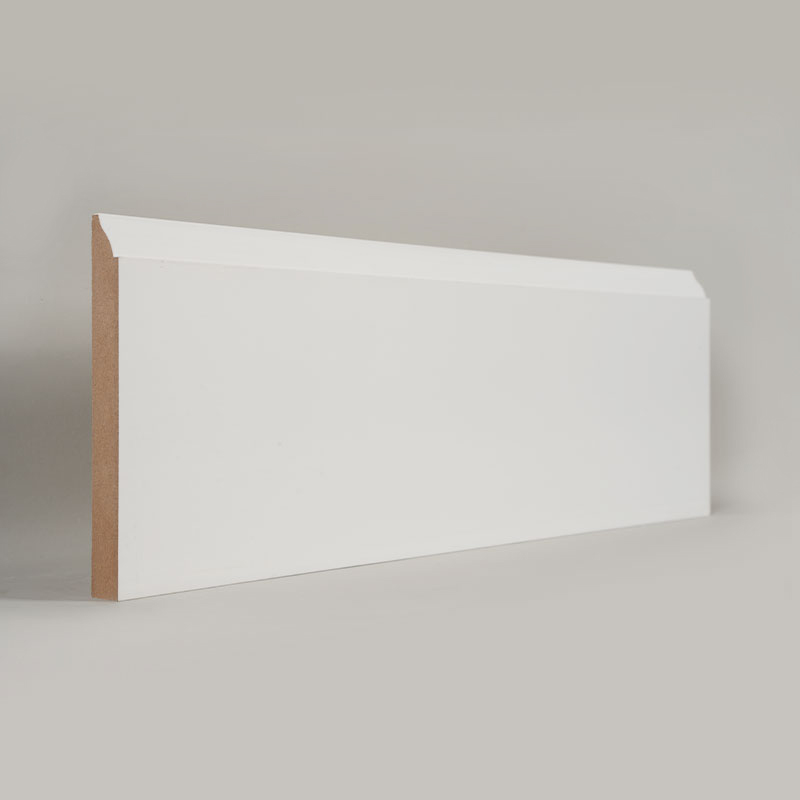

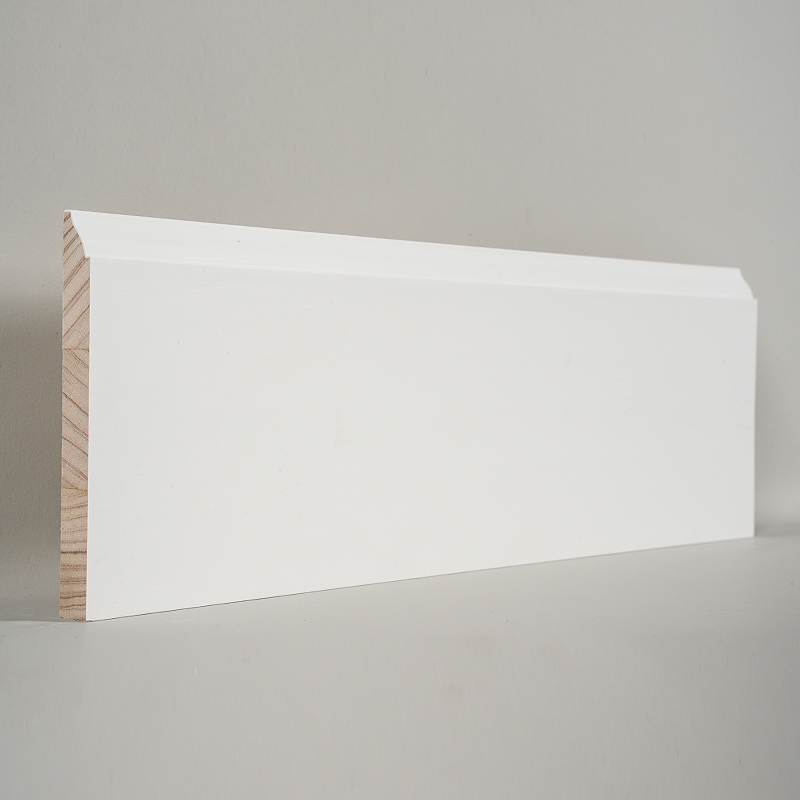

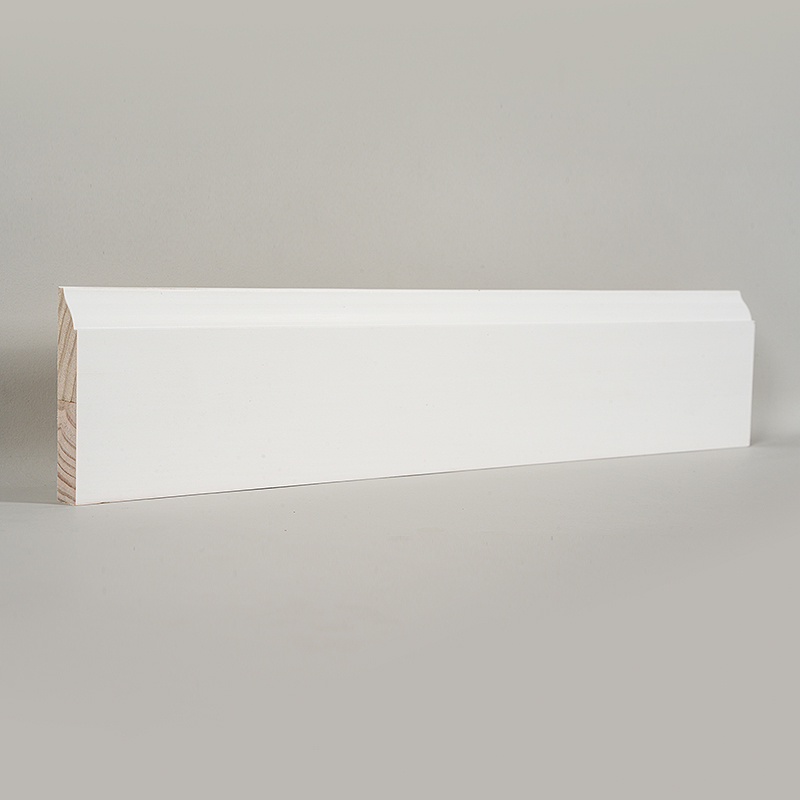

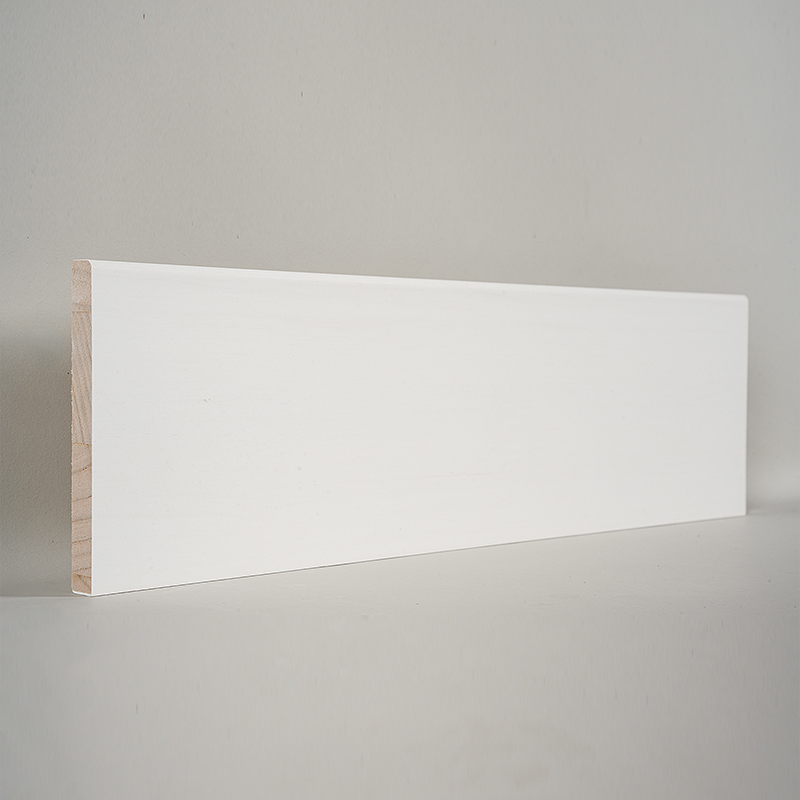

A white primed skirting baseboard refers to a skirting product that has been coated with a uniform primer layer before installation. These boards may be made from MDF skirting board, solid wood, plywood, or engineered wood, depending on the performance requirements of the application.

Its industry positioning includes:

(1) Wall Protection and Structural Transition

Skirting boards protect the wall base from abrasion, impact, and cleaning chemicals while covering construction gaps between floors and walls. By reinforcing the lower wall area, they maintain long-term structural integrity.

(2) Aesthetic Enhancement and Visual Continuity

The pre-primed white surface provides a clean, smooth base for final finishing. It integrates well with modern, minimalist, Scandinavian, traditional, or contemporary interior themes.

(3) High Compatibility and Installation Efficiency

The factory-applied primer improves surface uniformity, reduces on-site processing time, and increases compatibility with various interior moulding and home decoration materials systems.

Technical Characteristics That Define High-Quality White Primed Skirting Boards

To meet the expectations of modern construction projects, skirting boards must satisfy multiple performance indicators including stability, flatness, coating adhesion, and environmental compliance.

(1) Stability and Density of Base Material

High-quality boards rely on stable base materials:

- MDF skirting offers uniform density and is ideal for detailed profiles.

- Solid wood skirting provides natural durability and texture.

Regardless of type, moisture content control and dimensional precision are essential for long-term performance.

(2) Primer Coating Quality and Adhesion

The primer layer is critical for:

- sealing wood fibers

- preventing paint absorption

- increasing surface hardness

- improving final coat adhesion

- reducing risks of cracking, staining, or discoloration

Common options include UV primers, PU primers, or water-based primers, each with distinct sealing properties.

(3) Surface Finishing Precision

A high-end white primed skirting board typically undergoes:

- precision sanding

- uniform primer application

- structured sealing

- density-controlled coating

This ensures a smooth finish with minimal surface defects and excellent compatibility with topcoat paints.

Why Primed Skirting Boards Have Become an Industry Standard

The primed finishing structure plays a decisive role in overall product quality, leading to broad industry adoption.

(1) Superior Paint Absorption and Color Uniformity

The primer prevents uneven absorption, allowing the final paint to adhere smoothly and evenly across the board.

(2) Enhanced Durability and Protection

Sealed surfaces resist moisture, deformation, and surface wear, extending service life.

(3) Reduced On-Site Labor Costs

Since priming is completed in a controlled factory environment, installers only need to apply the topcoat, improving efficiency.

(4) Universal Compatibility with Surface Coatings

White primed skirting boards work well with:

- water-based paint

- UV topcoat

- matte or gloss finishes

- custom-color systems for interior trims

This adaptability makes them ideal for diverse project requirements.

Application Scenarios across Residential and Commercial Markets

White primed skirting boards are widely used in:

- residential interior decoration

- commercial office remodeling

- hotels, schools, and public buildings

- integrated wooden wall panel systems

- flooring transition systems

- high-end interior moulding and interior trims installations

Their consistent appearance, customizable profiles, and long-term performance make them a preferred choice for architects, designers, and contractors.

Manufacturing Technology and Process Standards

The performance and reliability of a white primed skirting baseboard are highly dependent on its production technology. The precision of equipment and the degree of process control directly influence coating uniformity, fiber sealing, and dimensional stability.

Huzhou Huicheng Home Technology Co., Ltd. has established a technologically advanced production system, operating at the forefront of the industry with:

(1) Fully Automatic Mud Coating Line

Ensures consistent coating thickness and smooth fiber sealing across all surfaces.

(2) UV Vacuum Spraying Line

Improves primer adhesion, surface hardness, and coating uniformity while minimizing bubbles or dust contamination.

(3) UV Printing Roll Coating Line

Provides stable texture, precise coating density, and excellent color consistency.

(4) 3D Printing Equipment and Technology

Enables complex patterns, enhanced surface textures, and high-end decorative effects for premium moulding applications.

Through these advanced facilities, the company ensures superior stability, durability, and surface performance across its product range.

How Enterprise Strength Directly Impacts Skirting Board Quality

The advantages of Huzhou Huicheng Home Technology Co., Ltd. illustrate how manufacturing capability influences industry product standards.

(1) Full Control over the Production Process

The company operates a fully integrated production chain—from raw material sourcing to coating and final delivery.

This guarantees:

- better product consistency

- stricter quality control

- reliable lead times

- efficient order management

(2) Agile and Flexible Customization

Skirting profiles, coating types, colors, surface textures, and lengths can be customized to match project requirements, offering flexibility for:

- residential construction

- large commercial projects

- international OEM/ODM production

(3) Local Expertise, Global Reach

Located in Huzhou, a major hub in China’s wood industry, the company benefits from:

- access to high-quality raw materials

- advanced manufacturing technology

- established supply chain resources

Combined with strong global logistics capabilities, the company effectively serves clients in multiple regions worldwide.

Industry Development Trends for White Primed Skirting Boards

As the demand for higher-performance interior materials increases, several development trends are emerging:

(1) More Environmentally Friendly Coating Systems

Water-based primers and high-solid UV coatings will gain mainstream adoption.

(2) Increasing Automation and Smart Production

Automated spraying, digital quality inspection, and intelligent packaging will accelerate.

(3) Precision Profile Design and Aesthetic Differentiation

More refined moulding shapes, smoother curves, and differentiated surface effects will become key drivers.

(4) Functional Integration

Future skirting boards may integrate:

- improved moisture resistance

- wiring channels

- sound-absorbing structures

- modular decorative elements

These innovations will redefine the role of skirting boards beyond decoration.

Conclusion

The white primed skirting baseboard has become a key element in modern interior finishing due to its functional durability, visual adaptability, and compatibility with diverse coating systems. Its performance is defined by the stability of the base material, the precision of the primer coating, and the quality of the manufacturing proces

English

English Español

Español