How Do Pre-Primed MDF Skirting Boards Improve Installation Efficiency and Surface Quality?

Introduction

As interior finishing standards continue to evolve toward greater precision, stability, and aesthetic consistency, pre-primed MDF skirting boards have become an essential component across residential and commercial design environments. Their uniformity, machinability, and paint-ready surface enable contractors, designers, and manufacturers to achieve refined visual results without compromising efficiency. Within this landscape, products such as white MDF skirting, moisture-resistant MDF skirting, and specialized MDF mouldings form the foundation of contemporary wall-to-floor transitions.

Material Composition and Structural Characteristics

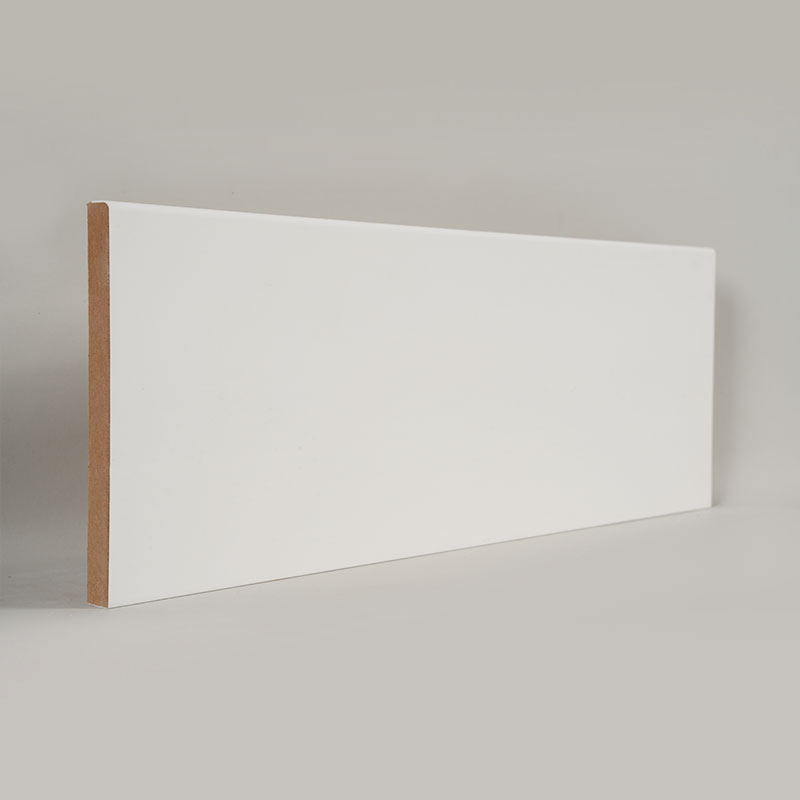

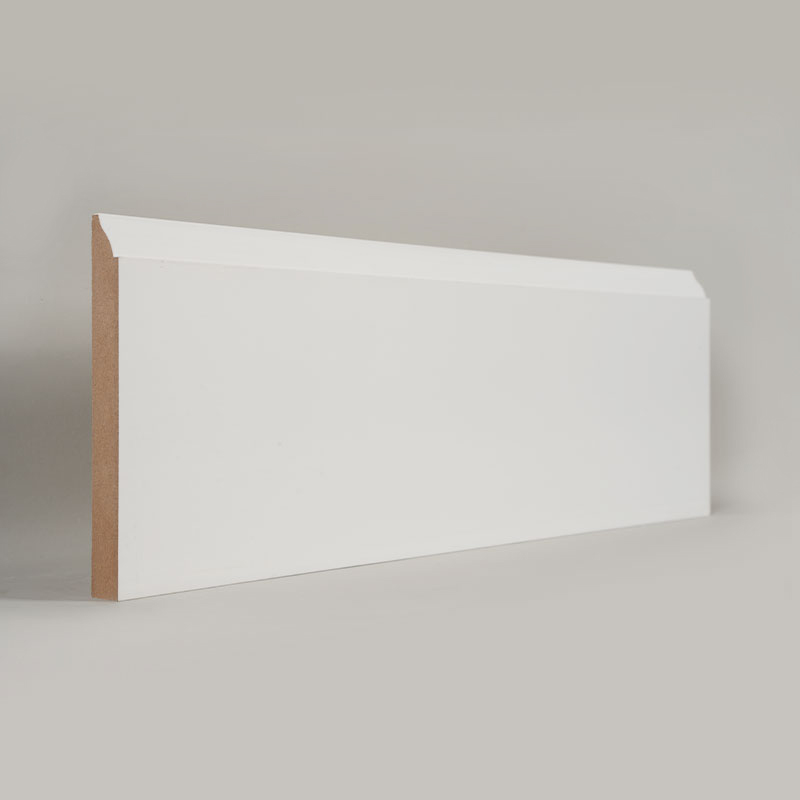

Medium Density Fiberboard (MDF) remains one of the most stable engineered wood substrates for skirting board applications. Its refined fiber structure ensures a homogeneous density distribution, providing predictable machining behavior when producing skirting board profiles including chamfered edges, ogee curves, torus styles, and contemporary square-edge designs.

For pre-primed MDF skirting boards, the substrate is particularly critical, as the primer coating requires a smooth and consistent surface to ensure strong adhesion. This structure delivers:

-

Dimensional Stability

The uniform fiber matrix resists warping and swelling better than natural softwoods, particularly when combined with moisture-resistant formulations. -

Surface Uniformity

MDF allows for a finely sanded base ideal for primer applications such as UV coatings or water-based primers. -

Machining Precision

Complex decorative contours can be shaped without grain tear-out, ensuring high-quality edges that require minimal finishing.

These attributes make MDF skirting board materials suitable for modern minimalist styles as well as traditional interior mouldings.

Primer Technology and Surface Finishing Advantages

The defining feature of pre-primed MDF skirting boards is the factory-applied coating layer. This pre-coating minimizes on-site labor and provides predictable adhesion for topcoat paints.

Primer Types

Typical primer systems used in the industry include:

- UV-curable primer coatings

- Water-based sealers

- Solvent-free environmentally compliant coatings

These coatings ensure the white MDF skirting surface is sealed, smoothed, and ready for final painting.

Benefits of Pre-Primed Surfaces

-

Reduced Installation Time

Contractors avoid multiple rounds of sanding and priming on-site. -

Improved Topcoat Quality

The pre-primed surface reduces paint absorption variations, yielding a uniform appearance. -

Enhanced Moisture Resistance

Properly sealed MDF surfaces resist humidity-induced surface fiber lifting.

Advanced Surface Processing at Huicheng

At this stage, technology becomes a key differentiator.

Huzhou Huicheng Home Technology Co., Ltd. adopts:

- Fully automatic mud coating lines

- UV vacuum spraying lines

- UV printing roll coating lines

- High-precision coating and 3D printing equipment

These systems create a highly consistent skirting board surface with controlled thickness, fine texture, and superior coating adhesion.

Manufacturing Integration and Process Reliability

A stable and precise manufacturing structure is essential for producing high-quality pre-primed MDF skirting boards. Vertical integration enhances product quality, traceability, and supply reliability.

Full Control over the Production Chain

Huzhou Huicheng Home Technology Co., Ltd. maintains end-to-end oversight of sourcing, machining, coating, quality inspection, and packaging.

Industry Advantages:

- Consistency in raw fiberboard density and flatness

- Traceable processing parameters

- Lower defect rates across large production volumes

This integrated structure ensures each meter of MDF skirting maintains consistent appearance and coating quality.

Flexible Customization Capabilities

Modern interior projects often require customization in:

- Profile dimensions

- Coating colors

- Surface textures

- Length formats

- Edge styling

Huicheng’s engineering and production teams support agile customization, enabling tailored solutions for both residential and commercial design requirements.

Production Scalability

Through efficient production lines and automation, Huicheng achieves:

- Daily output exceeding 15,000 meters

- Rapid processing of urgent orders

- Stable lead-time reliability

Such capacity assures consistent supply for large-scale project deployments.

Application Performance in Modern Interiors

The performance of white primed MDF skirting board and other MDF-based mouldings is defined by their interaction with interior environmental conditions and architectural expectations.

Aesthetic Performance

Skirting boards serve as a visual boundary and finish between wall and floor surfaces. Pre-primed MDF provides:

- Clean paint-ready profiles

- Refined, consistent edges

- Smooth surfaces free from wood knots or grain irregularities

These qualities support both contemporary minimalist designs and traditional decorative trim.

Durability and Stability

While MDF is not intended for wet areas, moisture-resistant versions significantly enhance durability. With proper sealing and installation, white primed MDF skirting board maintain their structural integrity even in environments with fluctuating humidity.

Installation Convenience

Advantages include:

- Lightweight handling

- Straight, uniform lengths

- Minimal need for corrective sanding

- Strong adhesion for joint fillers and topcoat paints

This allows installers to achieve professional finishes with reduced labor time.

Technological Innovation and Industry Trends

As the industry moves toward automation and high-efficiency surface preparation, several technological trends are shaping the future of MDF skirting.

Automated Coating Systems

Fully automated UV coating and vacuum spraying lines improve:

- Coating uniformity

- Edge coverage

- Production speed

- Environmental compliance

Precision Cutting and Profiling

CNC-based moulding cutters ensure profile symmetry and reduce material waste.

Color-Ready and Fully Finished MDF Skirting

Some manufacturers now integrate:

- Pre-painted surfaces

- Textured laminates

- Printed grain patterns

These innovations expand the application range beyond traditional white skirting boards.

Sustainable Practices

Eco-friendly binders, formaldehyde-controlled MDF substrates, and solvent-free coatings are becoming mainstream across global markets.

Logistics and Supply Reliability

To meet international project requirements, reliable logistics and packaging systems are essential.

Huzhou Huicheng Home Technology Co., Ltd. maintains an in-house logistics management system that ensures:

- Optimized domestic and international transport

- On-time delivery of bulk and customized orders

- Reduced product damage through refined packaging standards

This reliability supports long-term relationships with distributors, contractors, and OEM clients.

Conclusion

Pre-primed MDF skirting boards represent a stable, efficient, and visually refined solution for modern interior finishing. Their uniform substrate, precision-machined profiles, and factory-applied coatings ensure consistent quality and predictable installation performance. Enhanced by technological advancements—such as automated coating systems, CNC profiling, and moisture-resistant formulations—these products continue to strengthen their position in the global interior materials market.

English

English Español

Español