How do I prevent gaps between wood skirting baseboard molding and the wall?

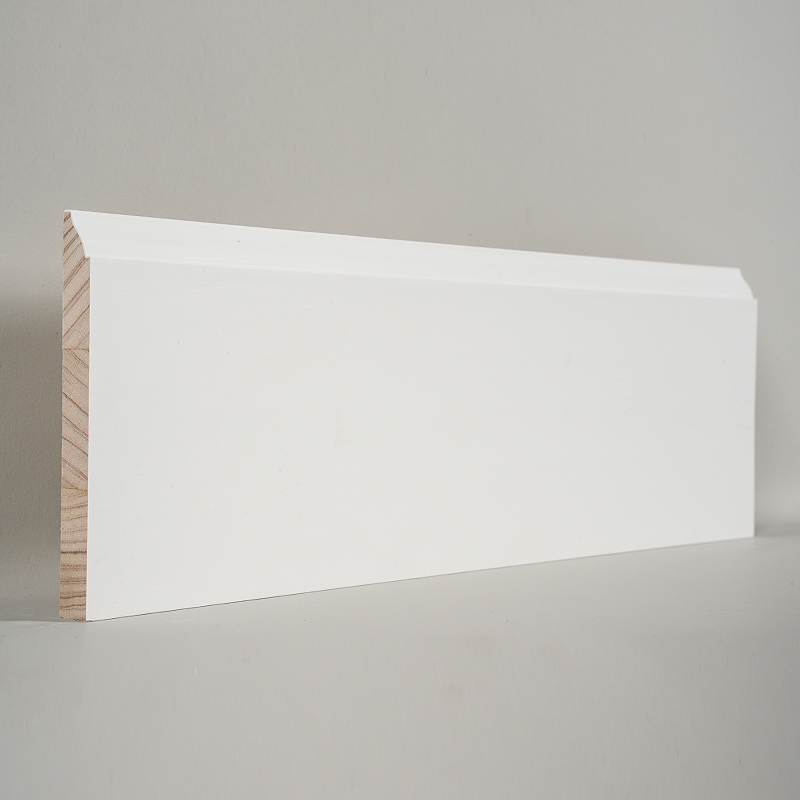

Wood skirting baseboard molding plays a crucial role in both the aesthetics and functionality of interior spaces. While often overlooked, the gap between the skirting and the wall can detract from a room’s visual appeal and compromise its protective function.

Understanding the Importance of Wood Skirting Baseboard Molding

Wood skirting baseboard molding, also referred to as wood skirting board or floor decor baseboards, serves several essential purposes in interior design. Its primary function is to protect walls from everyday wear and damage, while also concealing the junction between the floor and the wall. Proper installation ensures that no unsightly gaps appear, which could otherwise allow dust, debris, and moisture to accumulate.

Protection and aesthetics are the two pillars of effective skirting use. By choosing high-quality materials and precise installation techniques, homeowners and designers can maintain both the visual harmony of a room and the longevity of their walls. Gaps in skirting not only compromise appearance but also reduce its protective benefits.

Factors That Cause Gaps in Wood Skirting Baseboard Molding

Before addressing prevention strategies, it is essential to understand why gaps occur. The primary factors include:

1. Wall Irregularities: Most walls are not perfectly straight or flat, and even minor deviations can create gaps when skirting is installed.

2. Material Shrinkage or Expansion: Wood naturally expands and contracts with changes in temperature and humidity. Poorly selected wood skirting board material may lead to gaps over time.

3. Improper Installation Techniques: Incorrect measurements, uneven fastening, or lack of pre-adjustments can leave visible spaces between the skirting and the wall.

4. Flooring Installation Issues: If floorboards settle or shift after the skirting is installed, gaps may appear, particularly at the lower edge of the molding.

Understanding these factors highlights the importance of selecting the right wood skirting baseboard molding and following precise installation protocols.

Selecting the Right Materials

One of the most effective ways to prevent gaps is by choosing materials with dimensional stability. Huzhou Huicheng Home Technology Co., Ltd., with over 20 years of experience, manufactures a range of high-quality skirting solutions using both solid wood and engineered materials designed to minimize expansion and contraction.

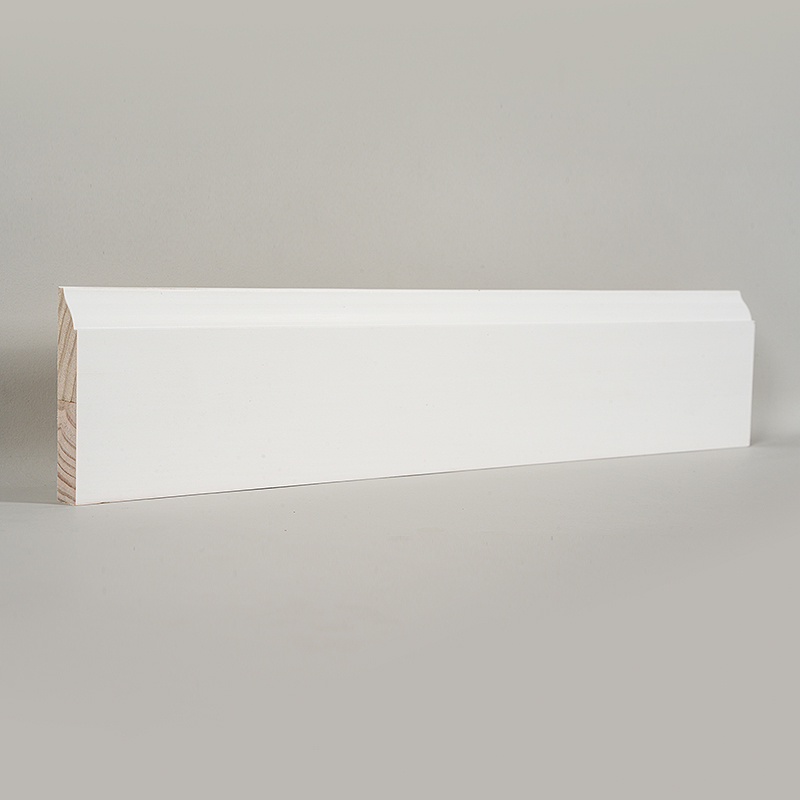

Solid Wood Skirting Board

Solid wood offers a classic and durable option, but it is sensitive to environmental changes. Woods like white oak, mangosteen, and radiata pine are highly recommended due to their low moisture content and superior stability.

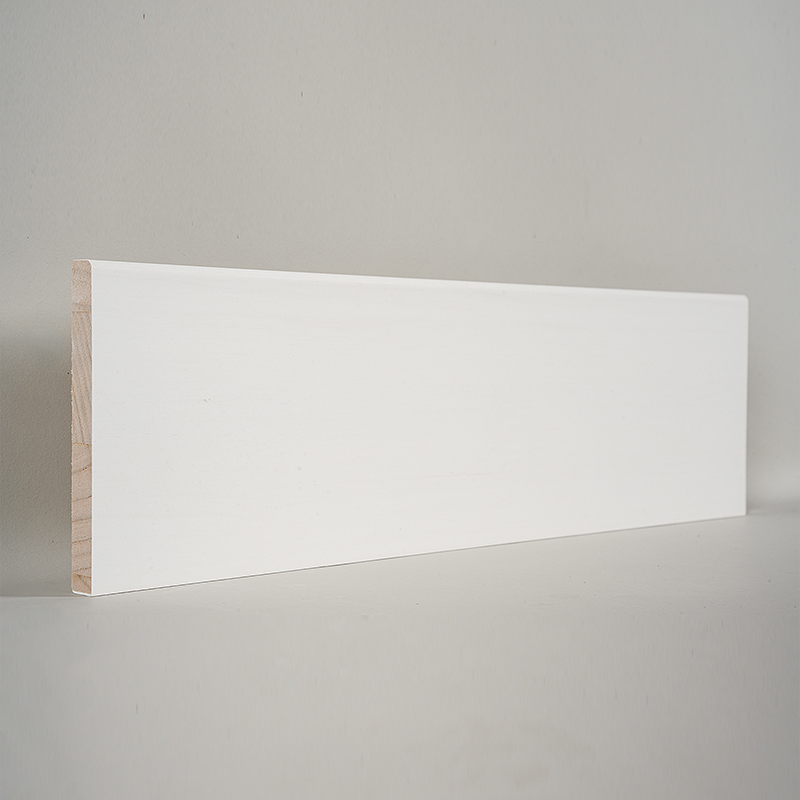

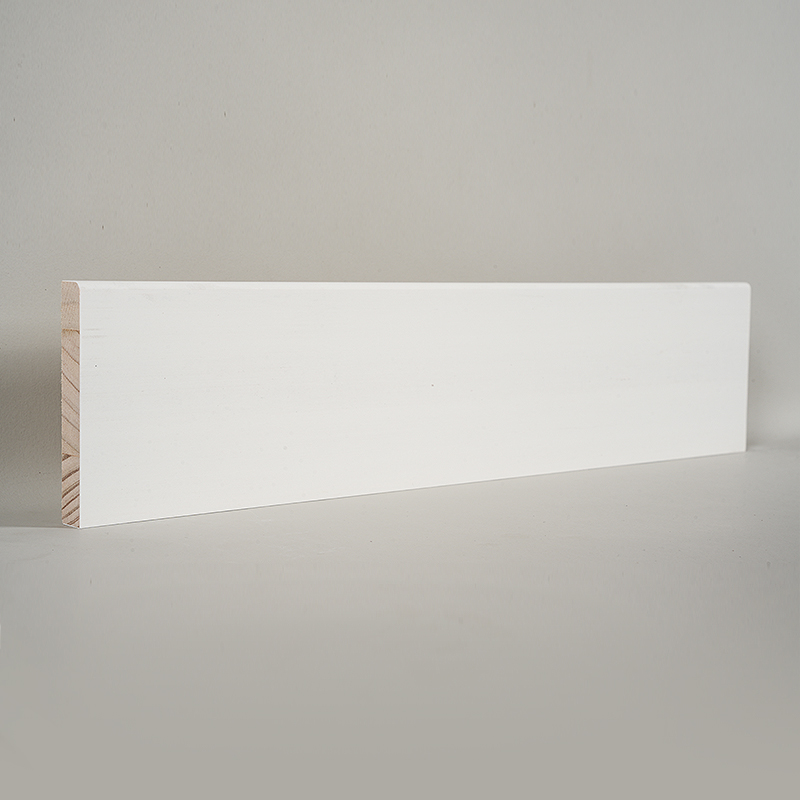

Engineered Wood and MDF Options

Engineered wood and medium-density fiberboard (MDF) provide enhanced stability and uniformity, making them ideal for areas with fluctuating humidity. When coated or finished properly, these materials can maintain a consistent fit against walls, reducing the likelihood of gaps.

PVC and Decorative Coatings

For commercial or high-moisture environments, floor decor baseboards made from PVC or veneer-coated materials offer resilience against warping while maintaining a polished appearance. These materials are particularly suitable for bathrooms, kitchens, and other challenging spaces.

| Material Type | Stability | Appearance | Recommended Usage |

|---|---|---|---|

| White Oak | High | Natural grain | Living rooms, hallways |

| Mangosteen Wood | Medium-High | Warm tone | Premium residential projects |

| Radiata Pine | Medium | Light tone | Residential, offices |

| MDF | High | Smooth finish | Modern interiors |

| PVC/Veneer-Coated | Very High | Custom colors | Moisture-prone areas |

Installation Techniques to Prevent Gaps

Even the highest-quality wood skirting board will show gaps if installation is not executed correctly. Professional installation methods focus on precision, measurement, and alignment.

Accurate Measurement and Cutting

Before installation, measure each wall section precisely and mark the intended skirting height. Using a miter saw or precision cutting tools ensures clean edges that align perfectly at corners. Huzhou Huicheng Home Technology Co., Ltd. emphasizes the use of advanced cutting equipment to maintain uniformity across batches.

Wall Preparation

Walls should be inspected for irregularities and corrected as needed. Filling minor wall imperfections or sanding uneven surfaces can provide a flush surface for skirting adherence.

Proper Fastening Techniques

Skirting boards can be fixed using nails, adhesives, or a combination of both. Ensure that:

- Nails are evenly spaced to prevent warping.

- Adhesives are applied consistently for a secure bond.

- Expansion gaps are respected where necessary, particularly with solid wood.

Accommodating Environmental Factors

Wood skirting molding must accommodate seasonal expansion and contraction. Experts recommend leaving a small 1–2 mm expansion gap along the top edge when necessary, which can be covered with caulk or paint for a seamless look.

Corner and Joint Management

Corners are often the most challenging areas. Using coping or mitering techniques ensures tight-fitting joints that prevent visible gaps. Accurate alignment at internal and external corners is essential for a polished appearance.

Finishing Touches and Gap Prevention

After installation, finishing work is key to maintaining the visual integrity of wood skirting baseboard molding.

Caulking and Sealing

High-quality, paintable caulk can fill minor gaps between the skirting and the wall. This not only improves aesthetics but also prevents dust accumulation.

Painting and Staining

Painting or staining the skirting ensures a consistent look, particularly if gaps are slightly visible. Opt for coatings that resist cracking and peeling, which helps maintain a seamless appearance over time.

Regular Maintenance

Routine cleaning and inspection of skirting boards help detect minor gaps early. Adjusting or re-securing sections before they worsen prolongs the life and function of the baseboards.

Benefits of Properly Installed Wood Skirting Baseboard Molding

Preventing gaps in skirting offers multiple advantages:

1. Enhanced Wall Protection – Skirting absorbs impact from furniture, cleaning tools, and foot traffic, protecting walls from damage.

2. Improved Aesthetic Appeal – Well-fitted baseboards create a cohesive, high-quality look in residential and commercial spaces.

3. Dust and Moisture Management – Gaps can harbor dust and moisture, potentially leading to wall degradation. Properly installed skirting mitigates this risk.

4. Longevity and Durability – Using high-quality materials like solid wood or coated MDF, combined with precise installation, ensures the skirting remains functional and attractive for decades.

Industry Perspective and Expertise

Huzhou Huicheng Home Technology Co., Ltd. has leveraged advanced technology and skilled craftsmanship to provide high-end and mid-range wood skirting board solutions. With a production area of 5,000 square meters and dozens of specialized personnel, the company ensures that each floor decor baseboards product meets stringent quality standards.

The company’s comprehensive production process—from raw material procurement to final logistics—enables both domestic and international clients to receive products with consistent fit and finish, minimizing installation gaps and improving overall satisfaction.

Additionally, Huzhou Huicheng has pioneered custom-painted and small-batch products, allowing designers and homeowners to select baseboards that perfectly complement specific interior aesthetics, while maintaining technical precision in installation.

Choosing the Right Supplier

Selecting a supplier with proven expertise in wood skirting baseboard molding is critical for achieving gap-free results. Key considerations include:

- Experience in material selection and understanding of environmental influences.

- Advanced machinery and technology to ensure uniformity and precision.

- Customizable options to match unique project requirements.

- Comprehensive production oversight to maintain quality from procurement to delivery.

By prioritizing these factors, homeowners and designers can significantly reduce the risk of installation issues and gaps.

English

English Español

Español