Understanding MDF Stair Nose: Structure, Functions, Application Benefits & Production Process

Company Background

Huzhou Huicheng Home Technology Co., Ltd. was founded in 2002 and is located in Hengjie Innovation and Entrepreneurship Industrial Park, Nanxun Town, Huzhou, Zhejiang, widely recognized as the capital of wooden flooring in China. With over 20 years of dedicated industry experience, the company has grown into a trusted manufacturer specializing in high-quality wooden skirting boards and decorative lines. Throughout its development, the company has combined innovation, craftsmanship, and advanced technologies to continuously meet the evolving needs of global customers.

The company operates a modern production facility of 5,000 square meters, staffed by 36 professional production and management personnel, more than 10 sales and administrative staff, and equipped with hundreds of advanced manufacturing machines. Its core production equipment—including fully automatic mud coating lines, UV vacuum spraying lines, UV printing roll coating lines, coating lines, and state-of-the-art 3D printing systems—positions the company at the forefront of the industry. These capabilities ensure stable production, efficient delivery, and consistent quality for both domestic engineering projects and international export orders.

With a complete production chain that covers raw material procurement, woodworking, paint formulation, PVC/veneer coating, and final logistics delivery, Huzhou Huicheng Home Technology Co., Ltd. maintains full control over quality at every stage. The company’s daily production capacity exceeds 15,000 meters, including more than 8,000 meters of painted products in mass production. Since 2025, the company has established a small-batch custom painting team to better meet personalized project needs, further enhancing customer satisfaction and serviceability.

What Is an MDF Stair Nose?

An MDF stair nose is a specially shaped molding installed at the edge of stair treads to reinforce the surface, improve step safety, and add decorative appeal. Made from medium-density fiberboard, it provides a uniform, smooth, and stable edge solution suitable for modern residential and commercial staircases. Its versatility in coating, surface texture, and color makes it compatible with different flooring materials such as laminate, engineered wood, and SPC flooring.

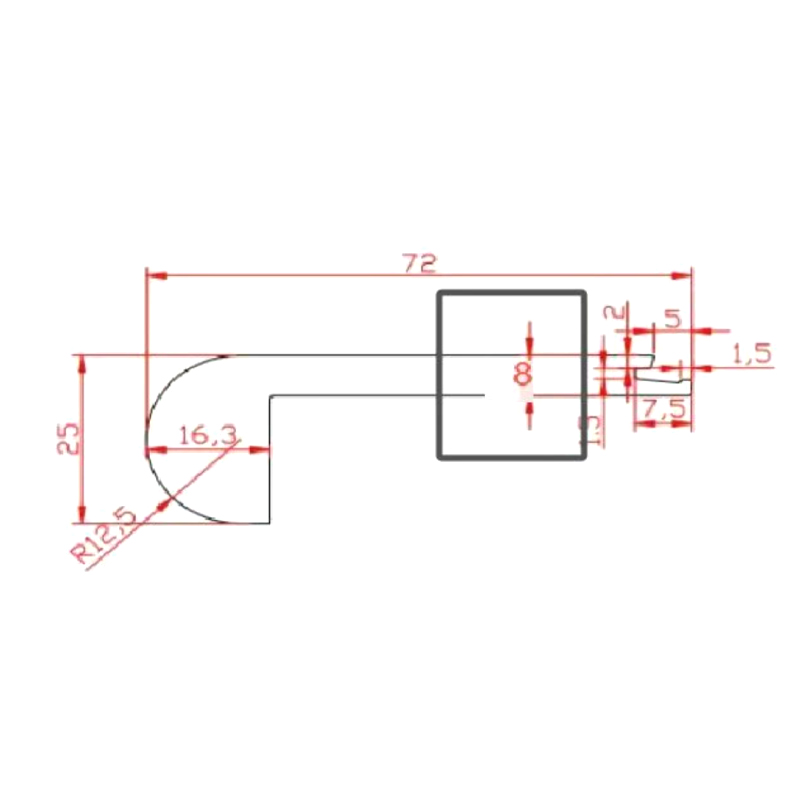

Structure of MDF Stair Nose

MDF stair noses are engineered for durability, consistency, and aesthetic compatibility with surrounding flooring. A typical structure includes:

- High-density MDF core that provides structural stability

- UV-coated, PVC-covered, or veneer-covered surface for improved durability

- Profiled nose shape engineered for slip resistance

- Grooved underside designed for secure installation with stair treads

Typical MDF Stair Nose Structure

| Component | Description |

| MDF Core | Engineered fibers compressed for strength and density uniformity |

| Surface Layer | Veneer, PVC film, or UV coating for protection and decoration |

| Profile Shape | Rounded, bullnose, square, or custom-milled shapes |

| Groove Design | Allows tight connection with stair tread for secure installation |

Main Functions of MDF Stair Nose

- Edge Protection: Prevents stair edge chipping and extends service life.

- Improved Safety: Reduces slipping and supports stable step transitions.

- Aesthetic Enhancement: Provides a clean, consistent finish matching the flooring.

- Durability: Offers wear-resistant surfaces suitable for high-traffic areas.

Application Benefits

1. Cost-Effective and Consistent

MDF stair noses deliver a balance between affordability and high-quality appearance. Their uniform density allows for precise machining, making them ideal for large-scale residential and commercial projects.

2. Highly Customizable Finishes

With advanced UV printing and coating technologies, Huzhou Huicheng Home Technology Co., Ltd. offers surface finishes that match a wide range of flooring designs. Custom colors, textures, and gloss levels can be produced efficiently.

3. Easy to Install and Compatible

The grooved underside design ensures smooth installation using adhesives or mechanical fasteners. The material is compatible with many flooring types and can be customized to match project specifications.

4. Reliable Production and Supply Capacity

The company’s complete production chain and strong equipment lineup ensure stable product output and reliable delivery for both domestic and international clients.

MDF Stair Nose Production Process Explained

The production of MDF stair noses involves a series of highly controlled steps to ensure dimensional accuracy, coating durability, and aesthetic consistency. At Huzhou Huicheng Home Technology Co., Ltd., the process is supported by advanced equipment and experienced technicians. Below is a detailed breakdown of the entire workflow:

1. Raw Material Selection and Preparation

High-quality MDF boards are selected based on density, moisture content, and fiber uniformity. These factors determine the performance of the final stair nose product. Boards are stacked in controlled environments to balance moisture and prevent warping.

2. Precision Cutting and Profiling

Using automated cutting equipment, MDF boards are trimmed into suitable sizes. They then pass through CNC profiling machines, where their characteristic nose shapes—round, bullnose, square, or custom profiles—are milled. This step ensures smooth edges and precise shapes that will align perfectly with stair treads.

3. Surface Treatment and Sanding

After shaping, each piece undergoes multiple sanding stages. Automatic sanding machines and manual polishing ensure a perfectly smooth surface. This step is essential for achieving flawless coating adhesion and a refined final appearance.

4. UV Coating or Veneer/PVC Lamination

Depending on customer requirements, the stair nose enters one of the following finishing lines:

- UV Vacuum Spraying Line: Applies durable UV-cured coatings for scratch and wear resistance.

- UV Roll Coating Line: Ensures even coating coverage with consistent thickness.

- PVC or Veneer Lamination: Uses advanced coating lines to bond surface films securely to the MDF core.

- 3D Printing: Reproduces wood textures with exceptional realism.

These advanced systems used by Huzhou Huicheng Home Technology Co., Ltd. enable surface precision, color stability, and diverse customization options.

5. Edge Sealing and Protective Layers

After surface finishing, the edges are sealed to prevent moisture absorption. High-quality edge-sealing materials ensure long-lasting stability and protect the MDF core in high-traffic areas.

6. Quality Inspection

Every batch undergoes rigorous inspection to ensure:

- Dimensional accuracy and profile consistency

- Surface coating adherence and smoothness

- Color uniformity and gloss level stability

- Resistance to wear, impact, and abrasion

The company’s commitment to detail ensures each product meets export-grade performance standards.

7. Packaging and Logistics

Finished stair noses are packaged in protective layers to prevent scratches during transport. The logistics team coordinates efficient shipping for both domestic and international clients, ensuring safe and timely delivery.

Why Choose MDF Stair Nose from Huzhou Huicheng Home Technology Co., Ltd.?

- More than 20 years of manufacturing experience

- Industry-leading automated production lines

- Strong capability for both mass production and small-batch customization

- Strict quality control and stable supply chain

- Professional team dedicated to customer satisfaction

English

English Español

Español