What Defines the Performance and Industry Value of Pine Wood Skirting Boards Today?

Introduction

Pine wood skirting boards have become a core component in modern interior finishing, serving both functional and aesthetic purposes across residential, commercial, and institutional environments. As the demand for natural materials and customizable architectural elements continues to rise, these products occupy a central role in flooring integration, wall protection, and visual detailing. Their versatility, machinability, and compatibility with diverse finishing technologies position them as a preferred option within the broader category of wooden decorative profiles.

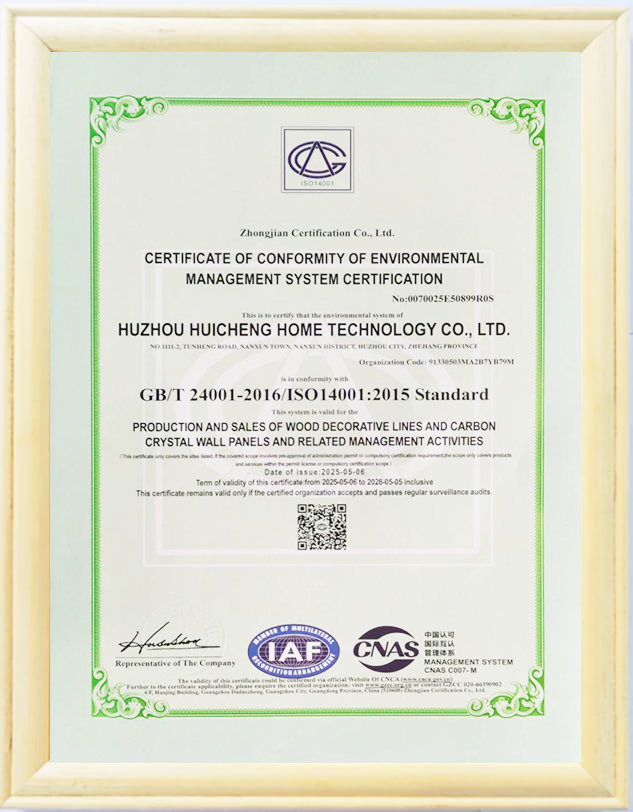

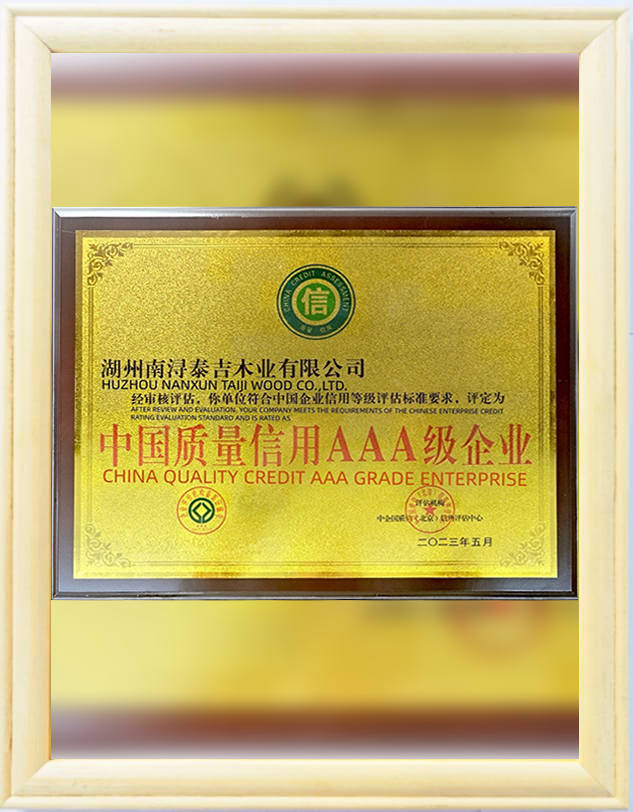

Within this evolving sector, Huzhou Huicheng Home Technology Co., Ltd. contributes to technological advancement and stable production capacity. As a professional manufacturer of wooden skirting boards, wooden acoustic panels, and related wood products, the company utilizes advanced equipment such as fully automatic mud coating lines, UV vacuum spraying lines, UV printing roll coating lines, coating lines, and 3D printing technologies, enabling consistent quality and scalable customization.

Material Characteristics of Pine Wood Skirting Boards

Pine wood is widely recognized for its stable structure, workable density, and favorable cost-to-performance ratio. These attributes determine how pine wood skirting boards behave during machining, coating, and long-term use.

Fiber Structure and Stability

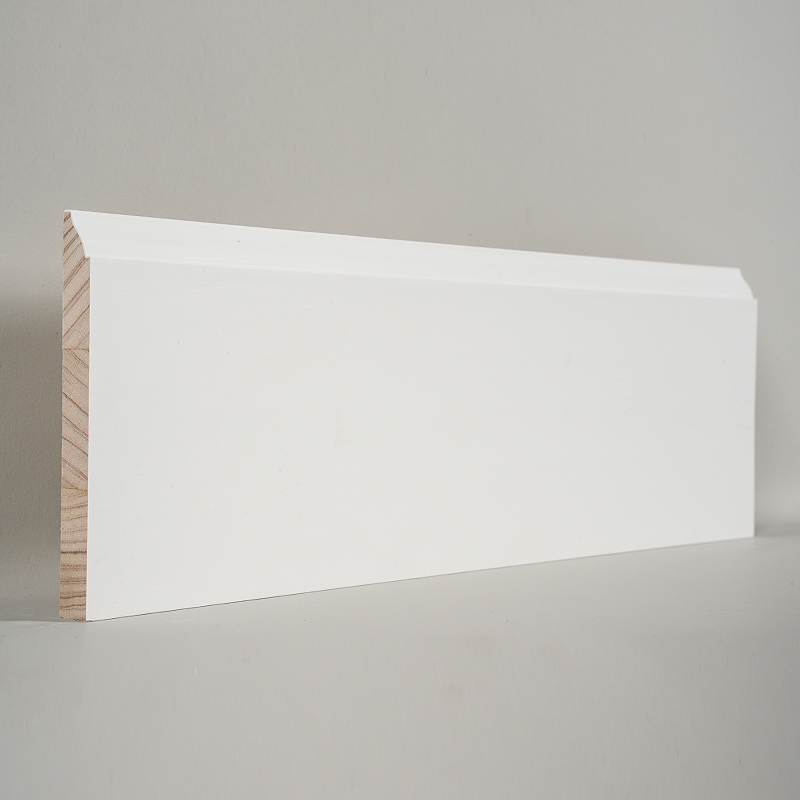

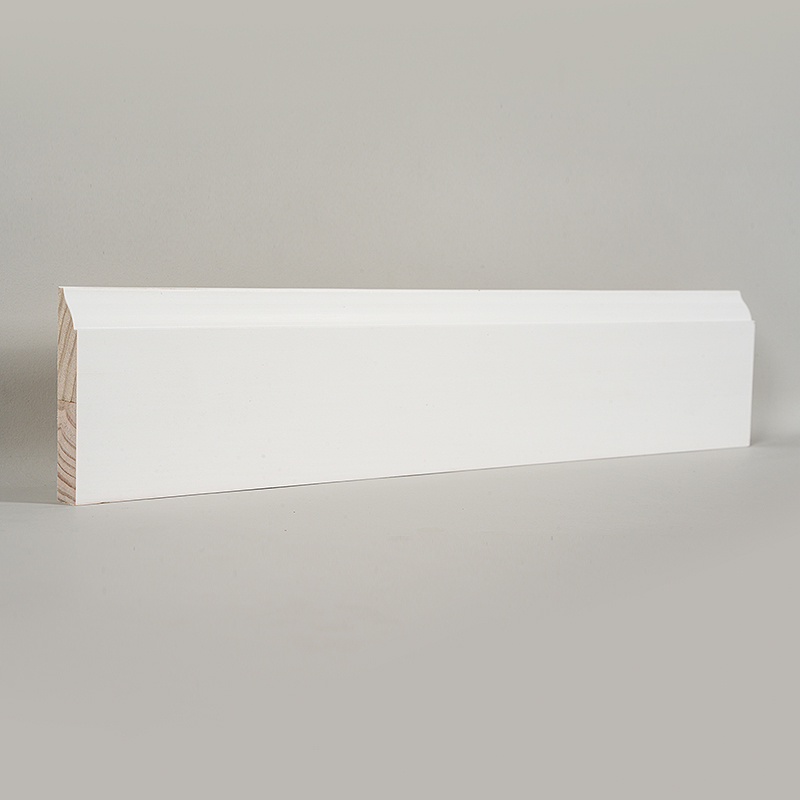

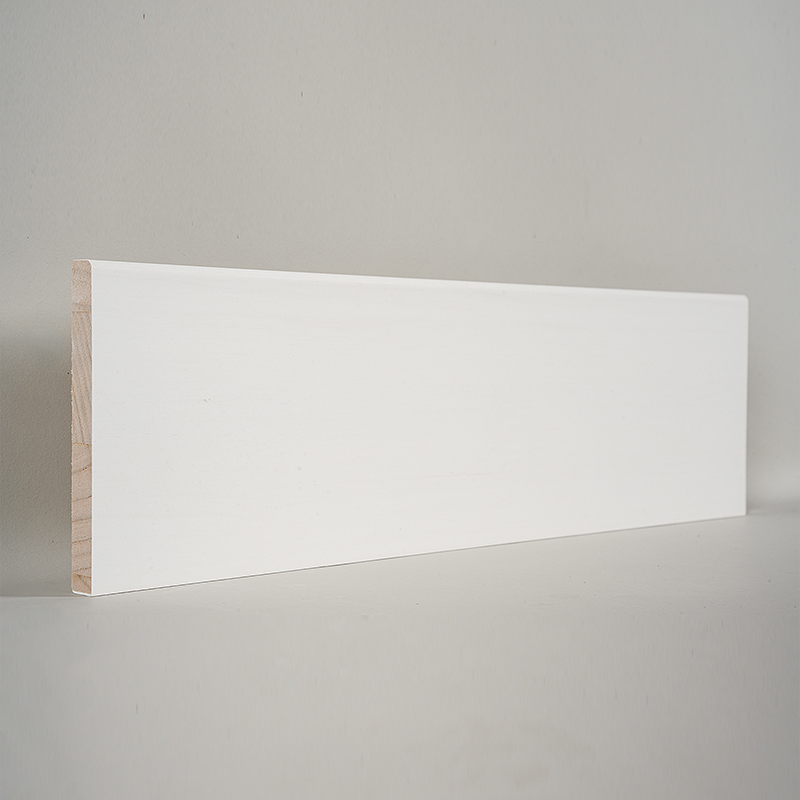

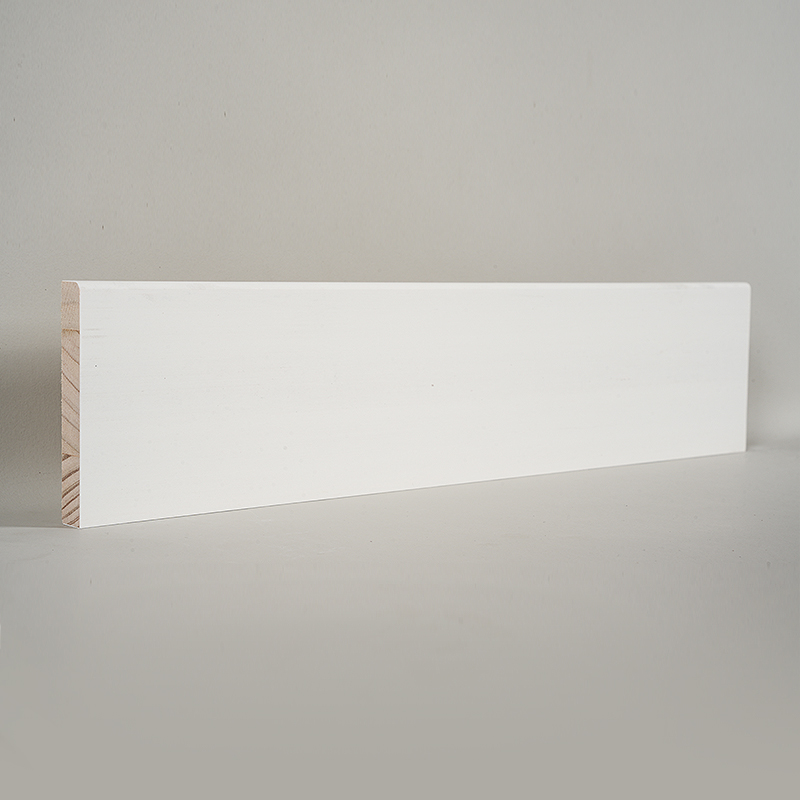

Pine has a relatively uniform grain direction, enabling predictable cutting behavior and reducing issues such as splintering or uneven edge formation. This facilitates precise profiling for various skirting shapes, including chamfered, torus, ogee, and shadow-gap designs.

Its dimensional stability also improves coating adhesion and reduces the risk of warping. When used as pine wood skirting boards in environments with consistent indoor humidity, the material maintains structural integrity with minimal deformation.

Workability and Machinability

Pine is well-suited for modern automated production systems, including CNC profiling, sanding integration, and high-speed coating equipment. It responds smoothly to milling tools, resulting in cleaner profiles and superior repeatability across production batches.

Huzhou Huicheng Home Technology Co., Ltd., with end-to-end control over material preparation and machining, leverages these characteristics to maintain consistency across diverse specifications.

Compatibility with Surface Finishes

Pine accepts a wide spectrum of finishes—primers, PU coatings, UV-cured coatings, water-based finishes, and decorative films—making it suitable for applications ranging from natural aesthetics to modern minimalist interior styles.

This compatibility broadens the functional and visual possibilities of white primed pine skirting boards, especially in markets where finishes such as white wood skirting boards are in high demand.

Processing Requirements and Precision Manufacturing

End-to-End Production Control

A critical performance determinant is how thoroughly the manufacturer controls the production chain.

Huzhou Huicheng Home Technology Co., Ltd. maintains complete oversight from raw material selection to machining and final finishing.

Advantages include:

- Stable raw material grading

- Predictable machining performance

- Reliable dimensional accuracy

- Consistent surface quality

- Reduced defect rate through integrated inspection

Full-process control ensures that pine wood skirting boards meet uniform standards even when customized in large quantities.

Advanced Coating and Printing Technologies

The finish quality depends heavily on coating technologies.

The company’s adoption of fully automatic mud coating lines, UV vacuum spraying lines, and UV printing roll coating lines provides several advantages:

- Increased surface uniformity

- High-efficiency curing

- Precise texture reproduction

- Enhanced durability against abrasion and cleaning

- Consistent gloss and color stability

These technologies enable the creation of coated pine wood skirting boards, colored profiles, and digitally textured surfaces that replicate, for example, oak or walnut patterns.

Integration of 3D Printing Technologies

3D printing enhances surface realism and allows tactile textures to be applied directly to skirting surfaces. This is particularly relevant for consumers seeking wood grain depth or decorative linear textures, enriching the offering beyond traditional flat-coated profiles.

Functional Roles of Pine Wood Skirting Boards

Wall Protection and Finish Alignment

The primary function of skirting boards is to protect lower wall sections from abrasion, impact, and cleaning tools. Pine’s elasticity and fiber composition help disperse surface pressure, preserving both wall finishes and skirting integrity.

Transition and Aesthetic Integration

Pine wood skirting boards serve as a structural transition between walls and flooring, concealing expansion gaps and enhancing spatial coherence.

Their visual role becomes even more significant in minimalist interiors, where clean lines and color harmony are essential.

Concealing Cables and Structural Imperfections

Many modern profiles include hollow channels suitable for cable management. Pine wood’s machinability makes it feasible to integrate these channels without compromising stability.

Surface Finishing Systems and Aesthetic Variation

Primed and Painted Finishes

White wood skirting boards represent one of the most widely adopted finishes. These typically use:

- Machine-applied primer layers

- UV-cured mid-coats

- Smooth, high-opacity topcoats

Pine provides an ideal substrate for these finishes because of its absorption characteristics and surface uniformity after sanding.

Natural Wood Finishes

For designs that emphasize natural grain visibility, semi-transparent coatings, oils, or water-based stains highlight pine’s warm tones and consistent grain patterns.

Decorative Film and Digital Printing Finishes

UV printing roll coating lines allow high-definition textures that mimic premium woods or produce unique patterns.

These engineered finishes expand design versatility, enabling white primed pine skirting boards to be used in both traditional and contemporary interiors.

Customization Capabilities and Market Adaptability

Flexible Specifications and Profiles

Market demands vary significantly across regions. Customization options include:

- Height, width, and thickness variation

- Profile geometry

- Pre-drilled configurations

- Surface finish customization

- Color standardization across large projects

Huzhou Huicheng Home Technology Co., Ltd. offers agile customization supported by integrated production lines, allowing tailored solutions for both small residential projects and large-scale commercial deployments.

Color and Texture Matching

Precise matching with flooring, wall panels, or doors is increasingly required. With advanced coating lines and digital printing capabilities, manufacturers can achieve stable color reproduction from batch to batch.

Suitable for Global Market Requirements

Located in Huzhou, a hub within China’s wooden flooring industry, the company benefits from:

- Access to reliable raw materials

- Streamlined supply chains

- Skilled technical workforce

- Efficient international logistics

These advantages ensure that pine wood skirting boards, white wood skirting boards, and other wood decorative profiles can meet global specifications and compliance requirements.

Installation Considerations and Performance in Use

Cutting, Fixing, and Joint Handling

Pine’s workability simplifies on-site installation. It accommodates:

- Nail fixing

- Clip systems

- Adhesive bonding

Precision manufacturing ensures better alignment, reduced on-site adjustment, and minimal visible gaps.

Surface Durability and Maintenance

Coating technologies used in production strongly influence long-term performance. UV-cured coatings generally offer enhanced resistance to cleaning chemicals, scratches, and repeated contact.

Regular dusting and occasional wiping are sufficient for maintenance, making white primed pine skirting boards suitable for environments ranging from private homes to high-traffic corridors.

Industry Trends Influencing Future Development

Growing Demand for Sustainable Materials

Pine wood, being renewable and widely cultivated, fits the increasing market expectation for environmentally responsible products.

Integration of Smart Manufacturing

Automated coating lines and digital monitoring systems improve production efficiency, product consistency, and supply chain transparency.

Expansion of Color and Texture Diversity

With continuous innovation in UV printing and 3D decorative technologies, pine wood skirting boards will support a broader design spectrum, aligning with personalized interior themes.

Customization as a Standard Offering

As interior design shifts towards customized environments, flexible production capabilities will be crucial.

Conclusion

Pine wood skirting boards have gained prominence due to their balanced blend of material strength, aesthetic adaptability, and production efficiency. Their compatibility with advanced coating systems, digital printing technologies, and diversified installation methods enhances their functional and decorative value.

English

English Español

Español