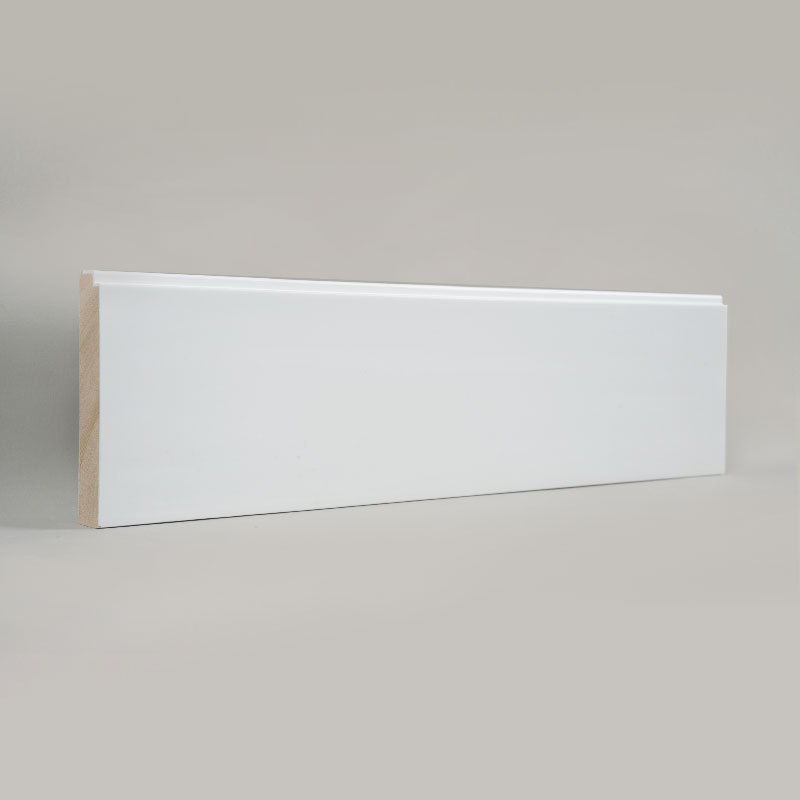

Excellent Structural Performance: Made from polyester fiberboard and MDF, using a scientifically formulated formula and high-pressure processing, this structure offers strong inherent bonding, effectively resisting the effects of temperature and humidity fluctuations, ensuring the wall panels resist warping and deformation over long-term use. Its load-bearing properties provide a solid protective layer for the wall surface, ensuring durability and extending the lifespan of building interiors.

Excellent Decorative Effect: The surface is clad on three sides with engineered wood veneer, resulting in clear, natural wood grain that preserves the delicate texture of the original wood. It seamlessly blends into any decor style, enhancing the quality and natural ambiance of any space.

Easy and Efficient Construction: The product features a convenient installation system for quick assembly, significantly reducing construction time. The removable structure facilitates future maintenance or reuse for space changes, effectively reducing costs and waste. A special paint treatment creates a dense, smooth protective film that easily removes dust and stains with a simple wipe.

Environmental and Healthy: The product utilizes a zero-formaldehyde manufacturing process, reducing the risk of indoor formaldehyde emissions. Its environmental performance far exceeds national standards, providing a healthier experience for both residential and public spaces.

Diverse Choices: A wide variety of colors are available, along with customizable craftsmanship and color combinations to meet diverse decorative needs for both home renovations and construction projects.

1. Eco-bonded PET-fiber core plus high-density MDF face—dual-density for quiet strength.

2. PET layer absorbs sound, MDF layer blocks and reflects it; together they cut room noise by up to 70 %.

3. Stable, warp-free, high-load and built to last.

4. Swap-in finishes, tool-free click install, fully reusable, wipe-clean surface.

5. Any color, print or texture—customised for your market.

6. Zero-formaldehyde assembly—safe for schools, clinics, homes, sound studios etc.