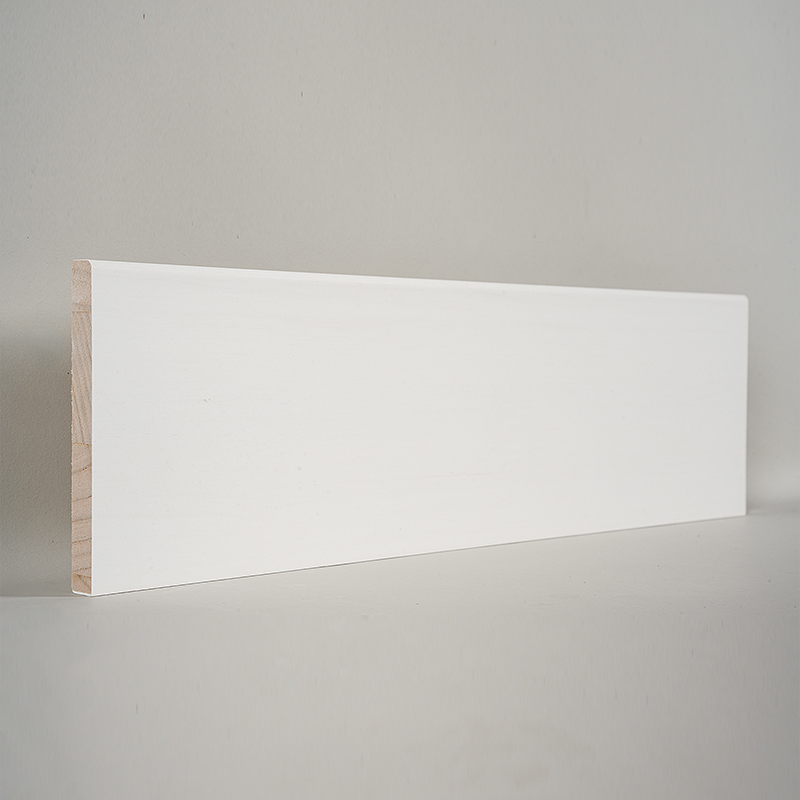

Base Material: The baseboard is constructed of high-density polyester fiberboard, offering excellent sound absorption properties. The surface layer utilizes highly eco-friendly medium-density fiberboard, ensuring a sturdy, flat, and environmentally friendly structure. This composite structure provides both acoustic performance and installation stability.

Craftsmanship and Surface Treatment: The surface is laminated with single-sided engineered wood veneer, resulting in clear, natural wood grain that preserves the delicate texture of the original wood. It seamlessly blends into any decor style, enhancing the quality and natural ambiance of any space.

Acoustic Noise Reduction: The product achieves high sound absorption through innovative physical structure. The base layer of high-density polyester fiberboard is filled with microscopic voids, effectively converting incoming sound energy into heat for efficient absorption. The dense MDF surface layer blocks and reflects residual sound waves, significantly reducing sound penetration. This synergistic effect of absorption and resistance creates a comfortable indoor environment.

Color and Visual Experience: The product features a variety of natural, warm wood grain effects, suitable for a variety of space styles, maintaining aesthetics while enhancing the overall harmony of the interior.

Practical Function: This wall panel combines aesthetics with practicality. Its sound-absorbing and sound-insulating properties make it suitable for applications requiring noise control and increased privacy. It improves the environment while providing reliable protection for the wall surface.

1. Eco-bonded PET-fiber core plus high-density MDF face—dual-density for quiet strength.

2. PET layer absorbs sound, MDF layer blocks and reflects it; together they cut room noise by up to 70 %.

3. Stable, warp-free, high-load and built to last.

4. Swap-in finishes, tool-free click install, fully reusable, wipe-clean surface.

5. Any color, print or texture—customised for your market.

6. Zero-formaldehyde assembly—safe for schools, clinics, homes, sound studios etc.