Why Are Pre-Primed Crown Mouldings Becoming the Preferred Choice for Modern Interiors?

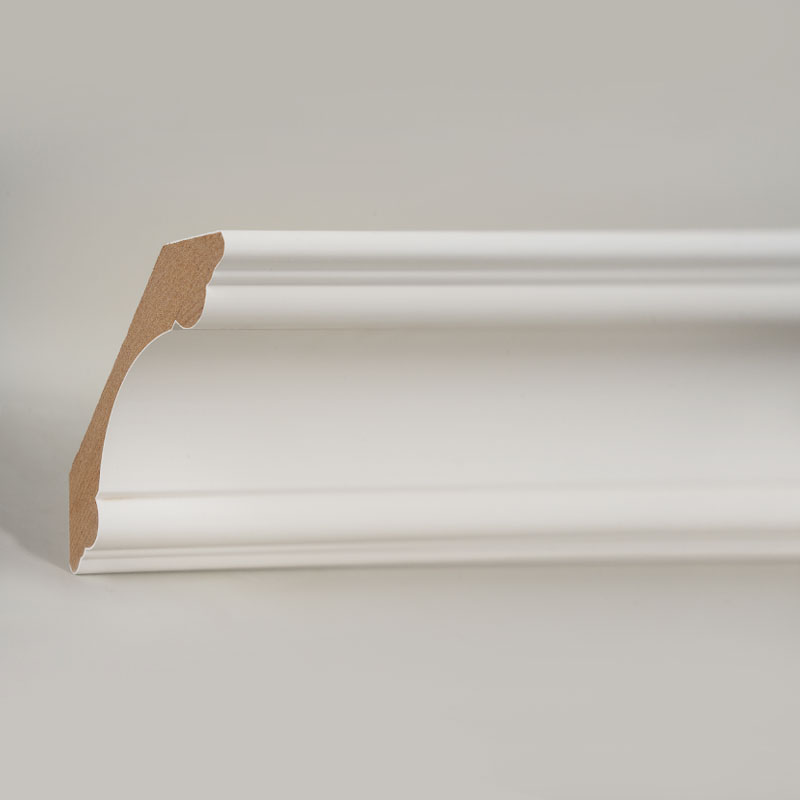

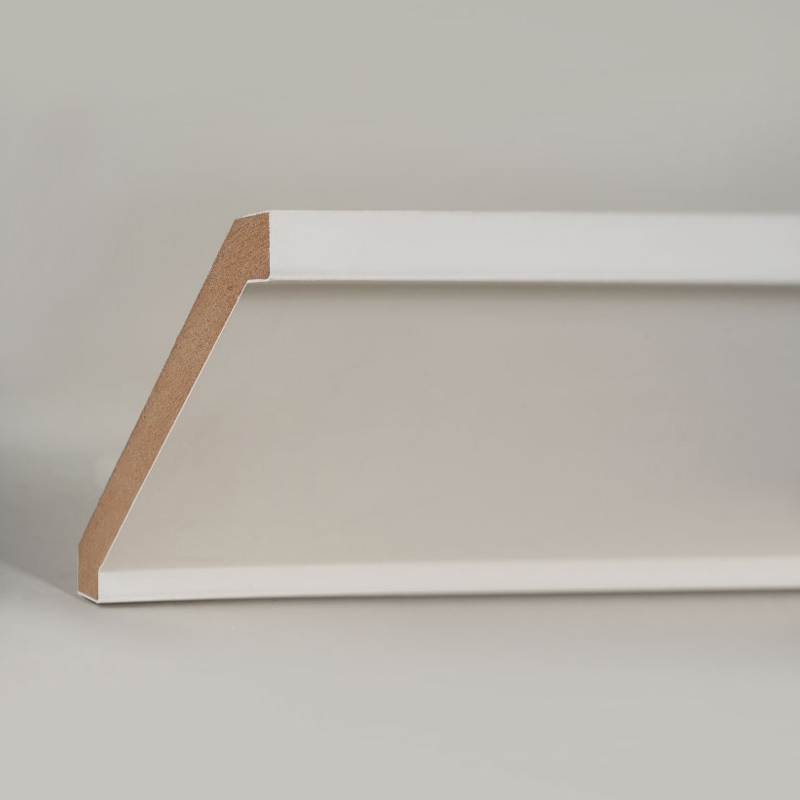

In the realm of interior design and architectural detailing, crown mouldings serve as more than mere decorative elements; they bridge the gap between walls and ceilings, creating a seamless visual transition while enhancing a room’s aesthetic appeal. Among the variety of options available, pre-primed crown moulding have gained significant traction due to their practical advantages, superior finish, and adaptability to diverse design schemes.

Understanding Pre-Primed Crown Moulding

Pre-primed crown moulding refers to wooden or engineered moulding products that come factory-primed with a high-quality base coat, ready for finishing or painting upon installation. Unlike traditional raw wood mouldings, which require onsite priming and sanding, pre-primed options streamline the installation process, offering a more consistent surface for subsequent finishes. This not only improves efficiency but also ensures a more uniform final appearance.

Key benefits include:

- Time efficiency: Pre-primed mouldings eliminate the need for labor-intensive priming onsite.

- Enhanced adhesion: Factory-applied primers are formulated for optimal paint adhesion, reducing the risk of peeling or flaking over time.

- Smooth surface finish: The priming process in controlled factory environments ensures minimal imperfections, enhancing the final painted appearance.

Material Selection and Construction

The most commonly used materials for white primed top corner moulding include MDF (Medium Density Fiberboard), solid wood, and engineered wood composites. Each material presents unique characteristics:

- MDF: Offers a smooth, uniform texture ideal for intricate moulding profiles. Its dense composition allows for precision in cutting and shaping.

- Solid wood: Provides natural grain patterns and structural integrity, though it may require more careful handling to prevent warping.

- Engineered wood composites: Combine the advantages of MDF and natural wood, often providing improved stability and resistance to humidity.

White primed crown moulding, in particular, is favored for its versatility in interior design. The neutral white base allows for direct painting or staining in complementary colors, making it compatible with both traditional and contemporary decors.

Manufacturing Techniques

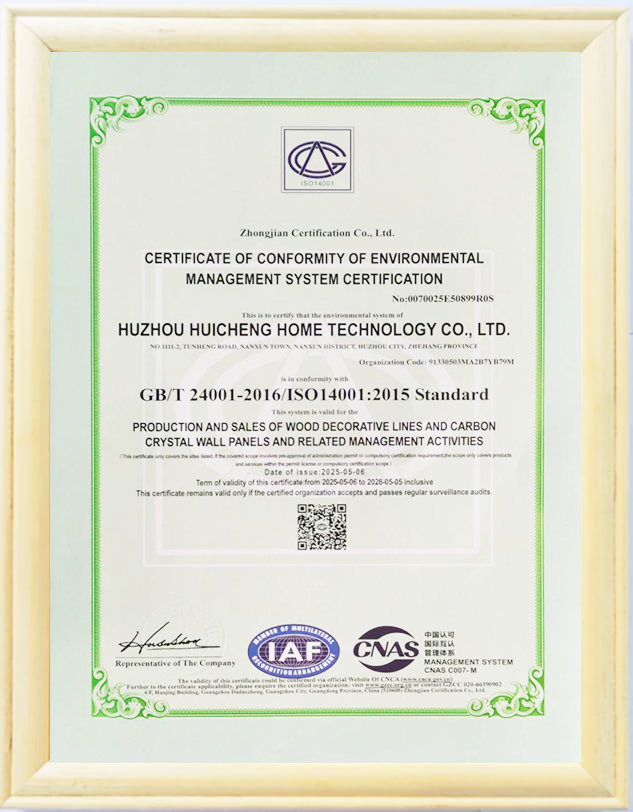

The production of white primed top corner mouldings involves advanced manufacturing techniques to ensure precision, consistency, and quality. Huzhou Huicheng Home Technology Co., Ltd. combines traditional craftsmanship with modern technology to produce high-quality plaster moldings. Core processes include:

- Cutting and profiling: Automated CNC machinery ensures precise dimensions and detailed profiles, from simple coves to elaborate classical designs.

- Sanding and smoothing: Prior to priming, mouldings undergo a meticulous sanding process to eliminate surface imperfections.

- Priming: Using advanced techniques such as UV vacuum spraying and fully automated coating lines, primers are uniformly applied to the moulding surfaces. This process not only improves adhesion but also enhances the durability of the finish.

- Quality inspection: A comprehensive quality control system checks each piece for defects such as warping, uneven primer coverage, or surface blemishes.

These processes allow manufacturers to deliver pre-primed crown mouldings that meet exacting quality standards, reducing installation challenges for contractors and homeowners.

Functional Advantages in Interior Design

Pre-primed crown mouldings provide numerous functional benefits beyond aesthetic appeal:

- Consistency: Factory-applied primer ensures uniform color and texture, which can be difficult to achieve with onsite priming.

- Durability: Controlled priming and finishing processes improve the moulding’s resistance to moisture and temperature fluctuations.

- Ease of installation: Pre-primed mouldings reduce preparation time for painters and carpenters, allowing faster project completion.

- Customization: White primed surfaces can be painted in any desired color, offering flexibility for design changes without compromising the integrity of the moulding.

- Reduced waste: By minimizing the need for multiple onsite treatments, pre-primed mouldings contribute to more efficient material usage and less environmental impact.

Sustainability and Environmental Considerations

Modern interior projects increasingly emphasize eco-friendly materials and sustainable practices. High-quality manufacturers integrate environmental considerations into the production of pre-primed crown moulding:

- Eco-friendly materials: Use of sustainably sourced wood and non-toxic primers.

- Energy-efficient production: Implementation of UV curing systems and automated production lines reduces energy consumption.

- Minimal VOC emissions: Low-VOC primers contribute to healthier indoor air quality during installation and throughout the product’s lifecycle.

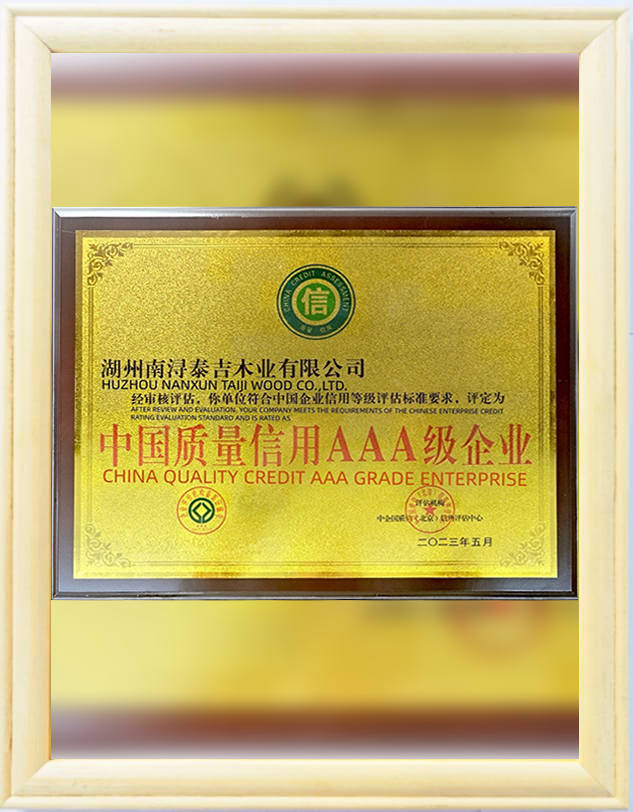

Huzhou Huicheng Home Technology Co., Ltd. exemplifies this approach, emphasizing sustainability while maintaining premium product quality. Their production facilities prioritize environmentally responsible methods without compromising performance.

Logistics and Global Market Reach

The distribution of white primed top corner mouldings requires careful management to maintain quality and ensure timely delivery. Huzhou Huicheng Home Technology Co., Ltd. leverages its strategic location in Huzhou, a central hub in China’s wooden flooring and wood product industry, to access high-quality raw materials and advanced manufacturing technologies. Their in-house logistics system ensures efficient shipping both domestically and internationally, allowing clients across different regions to receive products with minimal lead time.

Design Trends and Applications

Pre-primed and white primed top corner mouldings are increasingly utilized in diverse applications:

- Residential interiors: Enhancing ceiling transitions, adding elegance to living rooms, dining areas, and bedrooms.

- Commercial projects: Providing aesthetic detailing in hotels, office spaces, and luxury retail stores.

- Renovation projects: Facilitating rapid updates to interiors with minimal disruption and labor.

Current design trends favor clean lines, subtle profiles, and high-contrast combinations with wall colors, making white primed crown moulding an attractive choice for designers and architects seeking both flexibility and sophistication.

Quality Assurance and Long-Term Reliability

A key differentiator for pre-primed crown mouldings lies in quality assurance. Leading manufacturers implement rigorous inspection protocols throughout production. This includes dimensional checks, primer adhesion tests, and surface smoothness verification. Such attention to detail reduces post-installation issues, enhancing customer satisfaction and reinforcing long-term reliability.

Conclusion

The evolution of pre-primed crown moulding reflects the intersection of modern technology, design aesthetics, and practical functionality. These products offer efficient installation, consistent finish quality, and adaptability to diverse interior styles, all while supporting sustainable practices and long-term durability.

English

English Español

Español