How Do Material Choices Impact the Performance of Crown Moulding?

As an essential transition element between vertical and horizontal surfaces, wall to ceiling moulding plays a significant role in contemporary interior architecture. Beyond providing a smooth visual connection between the wall and ceiling, it enhances spatial hierarchy, expresses stylistic language, and contributes to refined detailing. With ongoing industrial upgrades, advanced production technologies, and the rising demand for precision craftsmanship, decorative crown moulding has evolved into a comprehensive building component that integrates structure, functionality, and aesthetics.

Functional Role: Structural Connection and Aesthetic Enhancement

In interior construction, the junction between the wall and ceiling often forms a visually abrupt boundary. Wall to ceiling moulding resolves this issue by creating a continuous line that visually softens the structural transition.

Its professional value can be summarized in several dimensions:

Visual Transition and Spatial Layering

- Eliminates harsh angles and creates smoother spatial continuity.

- Enhances depth through light-and-shadow variations along the moulding’s profile.

- Strengthens perceived ceiling height and balanced spatial proportions.

Style Expression Through Decorative Crown Moulding

Whether minimalistic, classical, transitional, or modern luxury, moulding profiles are central to defining the character of the interior.

Functional Integration With Ceiling and Lighting Systems

Certain moulding types assist with:

- Concealing LED strip channels

- Integrating curtain track recesses

- Covering installation gaps in suspended ceilings

- Supporting acoustic or ventilation components

Ensuring Construction Precision

High-quality moulding provides a clean, professional finish that compensates for minor inconsistencies at the wall-ceiling intersection.

Material Systems: Diversification and Performance Optimization

The decorative top corner moulding market has evolved from traditional wood to a broad portfolio of engineered materials. These materials determine dimensional stability, surface effect, workability, and long-term performance.

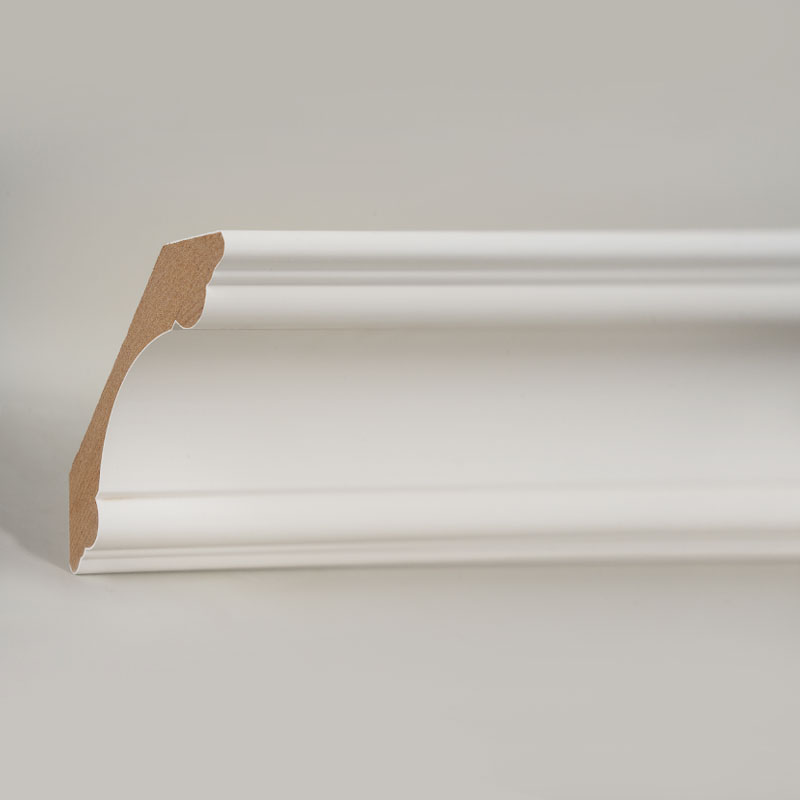

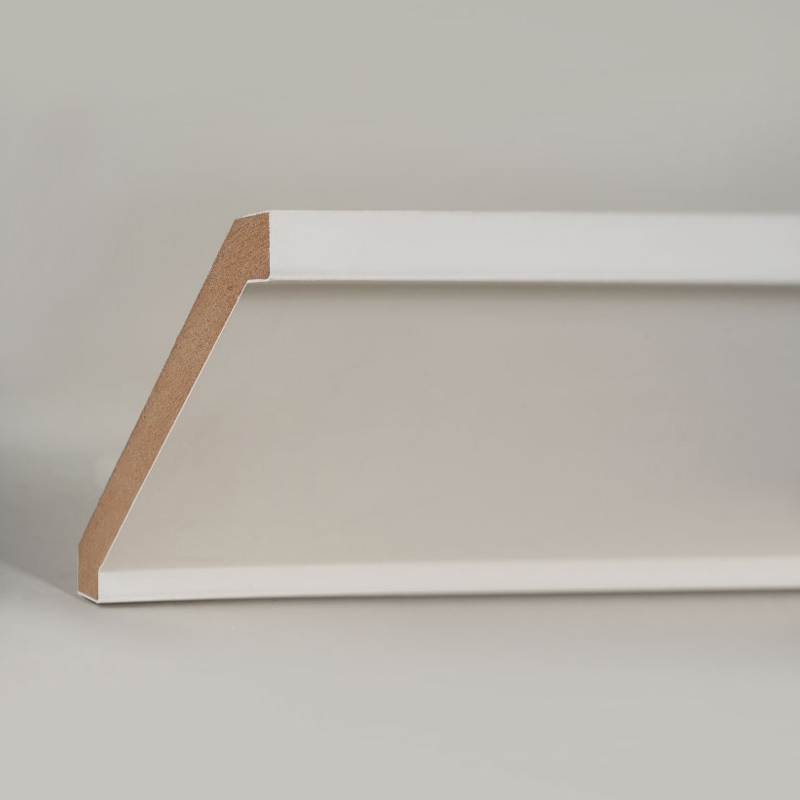

Wood and MDF (Medium-Density Fiberboard)

- Offers natural aesthetics and excellent machinability.

- Suitable for premium interiors, wood-panel systems, and high-end hospitality spaces.

- MDF mouldings are ideal for painted finishes, UV coatings, and textured surface printing.

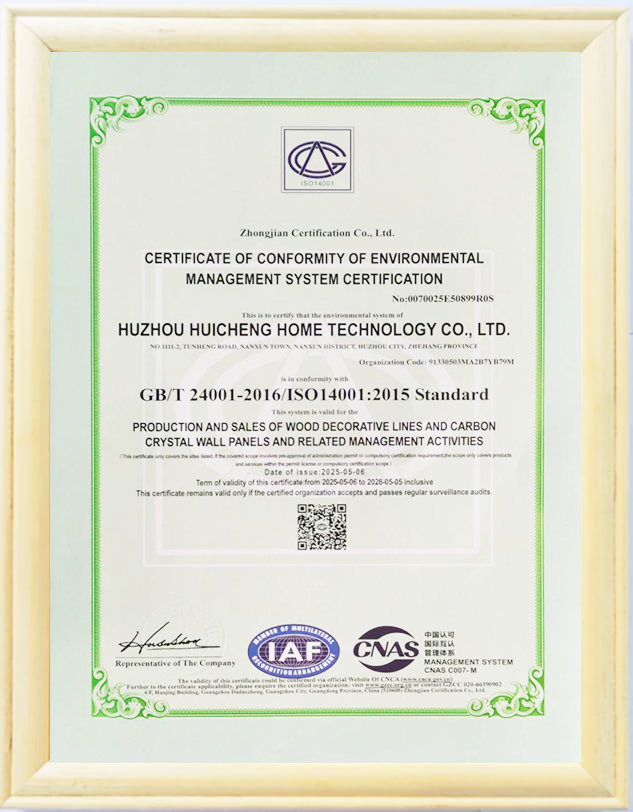

Huzhou Huicheng Home Technology Co., Ltd. excels particularly in this category. With expertise in wooden skirting boards, wooden acoustic panels, and structural trim components, the company utilizes industry-leading technologies such as:

- Fully automatic mud coating line

- UV vacuum spraying line

- UV printing roll coating line

- Advanced coating lines

- High-precision 3D printing technology

These capabilities ensure consistent, uniform coating quality and exceptional profile stability.

Polymer Materials (PVC, PU)

- Lightweight, moisture-resistant, and crack-resistant

- Suitable for kitchens, bathrooms, and commercial environments

- Easy to install in large areas with reduced labor intensity

Composite and Engineered Materials

- Designed for applications requiring enhanced durability or custom performance

- Beneficial for projects prioritizing lightweight construction and modular installation

Technology Trends: From Traditional Craftsmanship to Smart Production

The performance of decorative top corner moulding depends heavily on manufacturing precision and surface-finishing technology.

Automated Coating Replacing Manual Painting

Automation ensures:

- Uniform coating thickness

- Reduced color variation

- Higher surface durability

Huzhou Huicheng Home Technology Co., Ltd. stands out with its industry-leading automated finishing systems:

- UV vacuum coating ensures strong adhesion and even gloss.

- UV roll-printing enables natural wood grain reproduction with high wear resistance.

- 3D printing technology achieves precise contouring and fine detailing.

Digital Machining and Profiling Accuracy

Advanced CNC profiling ensures cross-section consistency, accurate dimensions, and tight installation tolerances.

Environmentally Conscious Production

The industry is increasingly adopting water-based coatings, recyclable base materials, and energy-efficient processes in alignment with global sustainability trends.

Design Trends: Simplicity, Versatility, and Functional Integration

The evolving preferences of modern interior design directly influence moulding development.

Minimalist and Streamlined Profiles

Clean lines and understated profiles have become mainstream in modern residential and commercial spaces.

Integrated Lighting Solutions

The demand for LED crown light moulding blends decorative effects with ambient illumination.

Acoustic Integration

In advanced hospitality, office, and entertainment spaces, moulding elements often connect to acoustic wall systems for seamless sonic and visual integration.

Textured and Specialty Finishes

High-end markets increasingly prefer moulding with:

- Wood grain textures

- Metallic effects

- Matte embossed surfaces

These finishes enhance design richness and spatial character.

Installation Logic: Precision Determines Final Results

Even the best decorative top corner moulding relies on proper installation to achieve a professional appearance.

Surface Preparation

Uneven wall or ceiling surfaces can create installation gaps, emphasizing the importance of substrate flatness.

Standardized Joint Construction

Proper techniques include:

- Mitre joints for outside corners

- Coping cuts for inside corners

- Seamless finishing through caulking and final coating

Lightweight Materials Improve Efficiency

Polymer and engineered mouldings significantly reduce installation time in large-scale projects.

Consistent Finish Quality

White-painted mouldings, in particular, require high uniformity in gloss, color tone, and surface texture.

Supply Chain Strengths: Capacity, Reliability, and Market Responsiveness

In the global moulding industry, manufacturers must excel not only in production quality but in logistics and scalability.

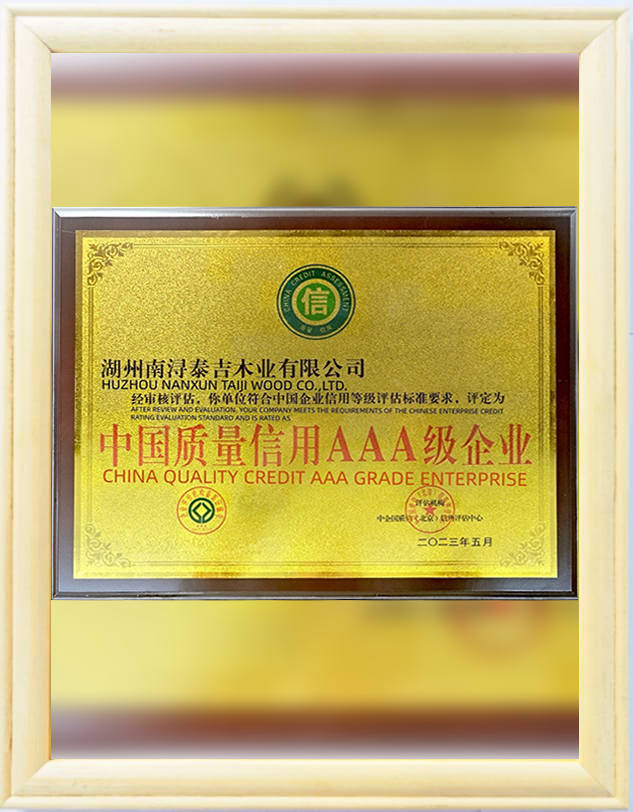

Strategic Location and Industrial Ecosystem

Located in Huzhou—China’s center for wooden flooring and wood-product manufacturing—

Huzhou Huicheng Home Technology Co., Ltd. benefits from direct access to quality raw materials and advanced manufacturing techniques.

High Daily Output for Large Orders

With an average daily production capacity exceeding 15,000 meters, the company easily supports:

- Large project requirements

- Urgent replenishment demands

- Global distribution needs

Efficient Logistics Management

Their in-house logistics system ensures punctual domestic and international delivery, minimizing customer lead times.

Strong Industry Relationships

Long-term partnerships with suppliers and distributors allow the company to remain updated with:

- New technologies

- Material innovations

- Market trends

This enables competitive pricing and rapid product development.

Comprehensive Customer Support

Huicheng provides dedicated service from initial consultation to after-sales follow-up, ensuring a seamless customer experience.

Application Scenarios: Versatility Across Architectural Sectors

Wall to ceiling moulding is essential across numerous architectural and interior environments:

- Residential homes and villas

- Hotels, resorts, and hospitality venues

- Retail spaces and showrooms

- Offices and commercial buildings

- Exhibition and cultural spaces

- Wood-paneling and acoustic system installations

Each setting has distinctive requirements for material durability, profile design, finishing style, and installation method.

Conclusion

As a key architectural component, wall to ceiling moulding contributes both functional precision and refined aesthetics to modern interior spaces. Driven by material innovation, digital manufacturing, and advanced finishing technologies, the industry continues to progress toward higher standards of quality and design versatility.

English

English Español

Español