Base Material: The core base material of this product is a composite structure of polyester fiberboard and MDF. The polyester fiberboard has excellent sound absorption properties, effectively absorbing ambient noise and reducing echoes, creating a peaceful and comfortable space. The internal MDF base provides solid support, ensuring the overall structural stability and flatness of the wall panel, resisting deformation and ensuring durability.

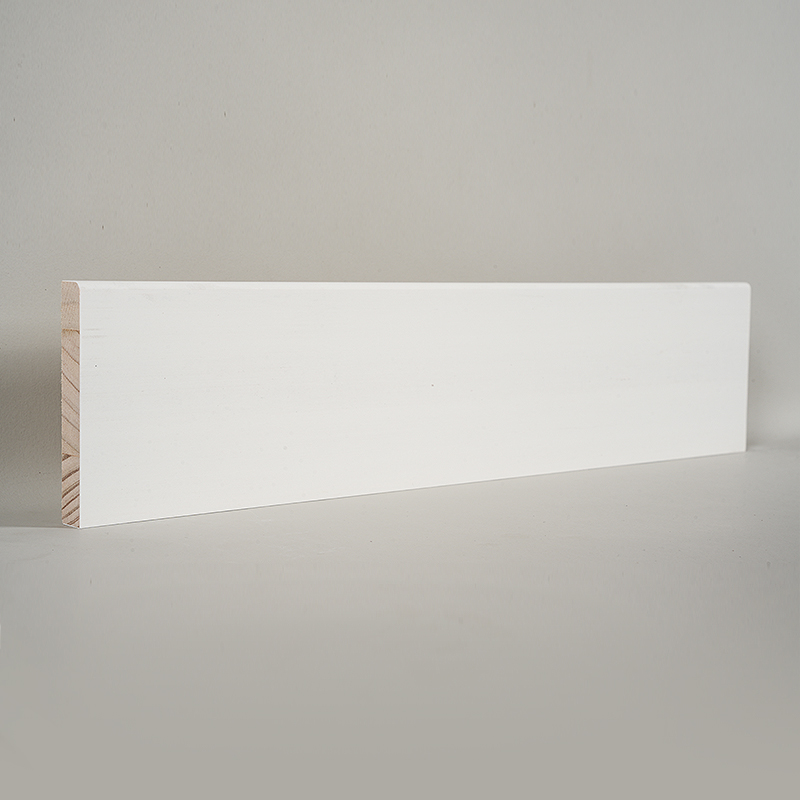

Surface Treatment: The outer layer is coated with a single-sided, paint-free, leather-textured PVC cladding, creating a complete protective layer for ready-to-install and enhanced moisture, abrasion, and scratch resistance. The triple-sided cladding ensures a precise and aesthetically pleasing edge finish.

Decorative Effects: A variety of standard colors are available, covering a wide range of color palettes, from classic solids to modern light tones. Matte and micro-textured finishes ensure a consistent and authentic color presentation, providing a simple, elegant, and harmonious solution for wall decoration, meeting individual design needs.

Easy Installation: Designed with practicality in mind, this product is suitable for spaces with specific acoustic requirements. Standardized dimensions and convenient installation methods help improve installation efficiency and reduce overall costs.

Environmental performance: Paint-free treatment avoids secondary painting, reduces environmental burden, and is safer and healthier in use.

1. Eco-bonded PET-fiber core plus high-density MDF face—dual-density for quiet strength.

2. PET layer absorbs sound, MDF layer blocks and reflects it; together they cut room noise by up to 70 %.

3. Stable, warp-free, high-load and built to last.

4. Swap-in finishes, tool-free click install, fully reusable, wipe-clean surface.

5. Any color, print or texture—customised for your market.

6. Zero-formaldehyde assembly—safe for schools, clinics, homes, sound studios etc.