What are the most durable types of wood architectural moulding for high-traffic areas?

Wood architectural moulding is a key element in enhancing the aesthetic and functional appeal of residential and commercial spaces. From wood decorative architectural trim to interior architectural trim, these components play a vital role in defining the character of a room while offering practical benefits, such as protecting walls from damage in high-traffic areas. Choosing durable moulding for areas like hallways, entryways, and commercial spaces is essential to maintain both appearance and longevity.

Understanding durability in wood architectural moulding

What determines the durability of wood architectural moulding?

Durability in wood architectural moulding is influenced by multiple factors:

- Wood species: Hardwoods such as oak, maple, and hickory are naturally denser and more resistant to wear compared to softwoods like pine or fir.

- Moisture resistance: Wood that is properly kiln-dried and treated resists warping, cracking, and swelling in areas with fluctuating humidity.

- Surface finish: High-quality coatings, such as UV-cured finishes or specialized varnishes, protect the surface from scratches, stains, and fading.

- Design profile: Profiles with minimal thin edges or delicate detailing are less prone to chipping or breaking in high-traffic areas.

Comparison of wood species for high-traffic areas

| Wood Species | Hardness (Janka Scale) | Durability | Common Applications |

|---|---|---|---|

| Oak | 1,290 | High | Hallways, commercial interiors |

| Maple | 1,450 | Very High | Staircases, baseboards |

| Hickory | 1,820 | Excellent | Entryways, areas with heavy foot traffic |

| Cherry | 950 | Moderate | Decorative trim in medium-traffic areas |

| Pine | 420 | Low | Lightly used spaces, cost-effective trim |

From the table above, hardwoods are generally preferred for high-traffic applications due to their superior wear resistance and ability to maintain structural integrity over time.

Types of durable wood architectural moulding

Solid wood moulding

Solid wood moulding is crafted entirely from a single piece of wood, offering natural strength and longevity. Its advantages include:

- High resistance to impact and denting

- Ability to be sanded and refinished multiple times

- Natural grain and texture that enhance interior aesthetics

Solid wood moulding is particularly suitable for interior architectural trim in areas such as staircases, corridors, and commercial lobbies where durability is a priority.

Engineered wood moulding

Engineered wood moulding combines wood fibers or veneers with adhesives to create a strong and stable product. Benefits include:

- Reduced susceptibility to warping and splitting

- Consistent size and shape across large orders

- Often more affordable than solid wood while maintaining durability

While engineered wood moulding may lack the unique grain of solid wood, its stability makes it an excellent choice for high-traffic areas where dimensional consistency is critical.

PVC-coated and veneer-coated moulding

Wood decorative architectural trim coated with PVC or veneer offers additional resistance to moisture, scratches, and abrasions. Key features include:

- Enhanced longevity in environments prone to humidity

- Easy maintenance with simple cleaning

- Available in a variety of finishes that mimic natural wood

These options are commonly used in commercial spaces or high-end residential projects where both aesthetics and resilience are required.

Manufacturing considerations for durable moulding

Quality control in production

Durable wood architectural moulding begins with rigorous manufacturing standards. Leading manufacturers, such as Huzhou Huicheng Home Technology Co., Ltd., ensure that each piece undergoes strict quality control. Factors considered include:

- Proper drying of raw materials to reduce moisture-related defects

- Precision cutting to maintain consistent profiles

- Application of protective coatings using advanced technologies such as UV vacuum spraying and 3D printing equipment

Customization and small-batch production

Since each project may have unique requirements, the ability to customize interior architectural trim is crucial. Huzhou Huicheng Home Technology Co., Ltd. has developed a dedicated team to handle small-batch custom-painted moulding, ensuring that even bespoke designs maintain durability standards without compromising quality.

Machinery and automation

Advanced machinery, including fully automatic mud coating lines, UV printing roll coating lines, and other cutting-edge equipment, allows manufacturers to produce wood decorative architectural trim at high consistency while minimizing human error. This technological integration contributes to the long-term durability of moulding in high-traffic applications.

Choosing the right profile for high-traffic areas

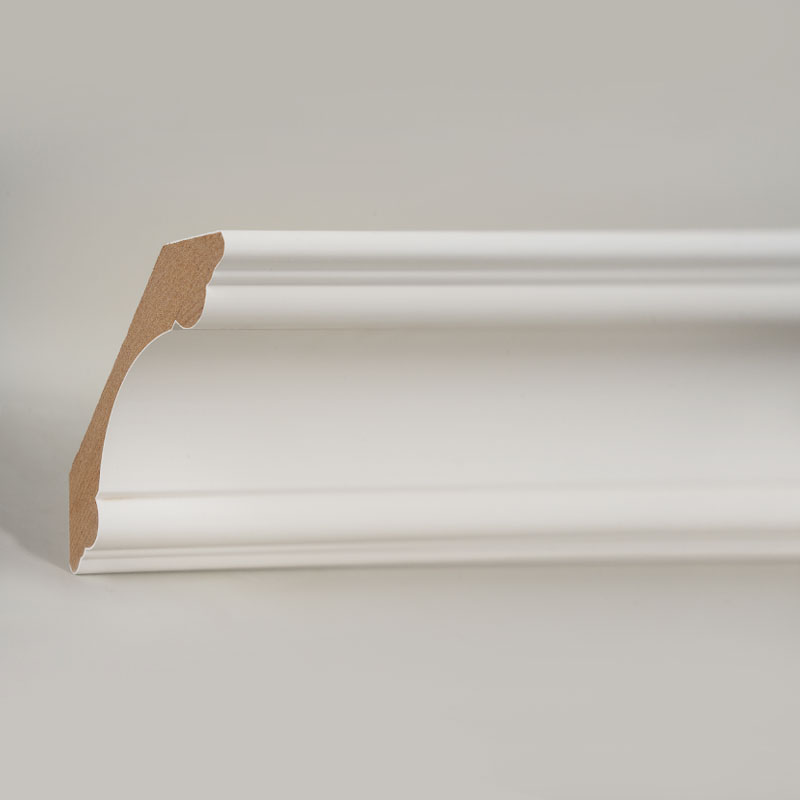

Simple versus ornate designs

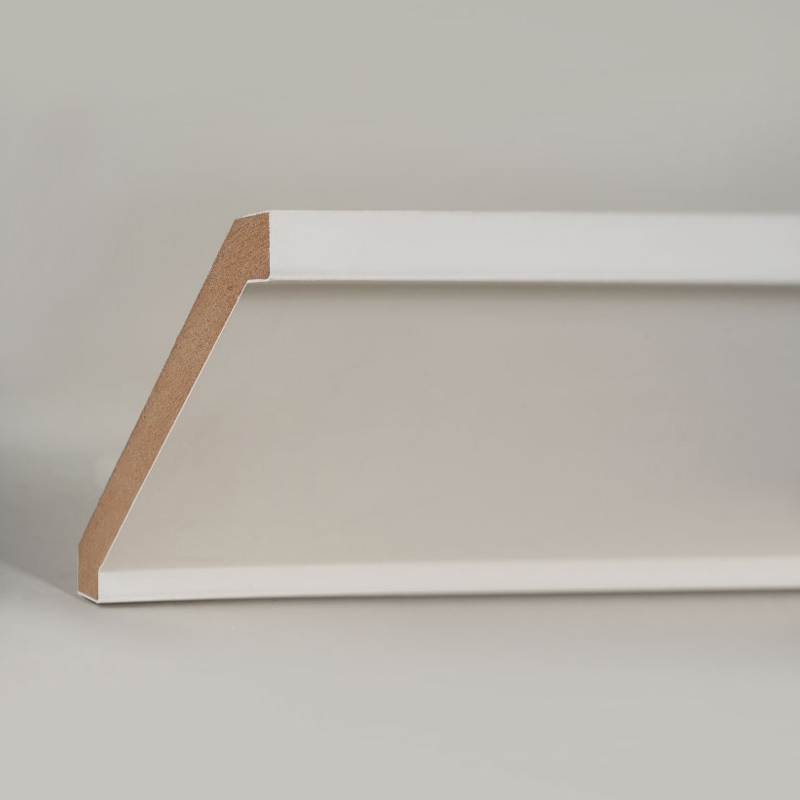

- Simple profiles: Rounded or straight-edged moulding is less likely to chip and easier to maintain. Ideal for corridors, entryways, and commercial areas.

- Ornate profiles: Decorative designs with intricate carvings may be visually appealing but are more susceptible to damage in areas with heavy foot traffic.

Crown, baseboard, and chair rail considerations

- Crown moulding: Protects the top edge of walls and enhances ceiling aesthetics. Durable options should be made from hardwood for long-term resilience.

- Baseboards: High-traffic areas benefit from thicker, solid wood baseboards with protective coatings to resist scuffs and impact.

- Chair rails: Positioned mid-wall to prevent furniture damage, durable hardwood rails provide both protection and style.

Maintenance strategies to extend durability

Even the most durable wood architectural moulding requires proper maintenance to maximize lifespan:

- Regular cleaning: Dust and dirt can cause micro-abrasions over time; use soft cloths or gentle brushes.

- Periodic refinishing: Applying a protective finish or polishing every few years preserves surface integrity.

- Humidity control: Maintaining indoor humidity levels between 40–60% prevents warping and cracking.

- Damage repair: Small scratches and dents can be repaired with wood filler or sanding without compromising the overall appearance.

Benefits of investing in durable wood architectural moulding

Durable interior architectural trim provides both functional and aesthetic advantages:

- Longevity: High-quality wood moulding withstands years of wear, reducing replacement costs.

- Enhanced aesthetics: Maintains visual appeal even in high-traffic areas.

- Increased property value: Premium trim contributes to perceived quality and craftsmanship.

- Low maintenance: Well-finished moulding requires minimal upkeep, saving time and effort.

Industry insights and trends

Demand for sustainable and high-quality moulding

The market increasingly favors wood architectural moulding that is both durable and environmentally responsible. Manufacturers are prioritizing responsibly sourced hardwoods and adopting sustainable production techniques to meet international standards.

Integration with modern interior design

Durable moulding is no longer purely functional. Designers and homeowners are choosing profiles that complement minimalist, contemporary, and classic interiors. Wood decorative architectural trim can be paired with accent lighting or painted finishes to create focal points while maintaining resilience.

Global standards and quality benchmarks

Leading manufacturers, such as Huzhou Huicheng Home Technology Co., Ltd., adhere to international quality standards. The use of advanced machinery, skilled craftsmanship, and complete production chains—from raw material procurement to final delivery—ensures that high-traffic areas are equipped with moulding that performs reliably over time.

English

English Español

Español